I-PEX High-Temperature Connector Products

Electric power is becoming mainstream due to technological innovations in automated driving and the growing use of environmentally friendly electric vehicles (EVs). To cope with the increased electronics used in automobiles, automotive developers must address high-speed data transmission, high-current and high-voltage situations while reducing the size and weight of components to saving space.

In addition, the increased number of modules installed means increased heat generated due to high currents, inside the housing of the modules. The use of heat-resistant components is becoming ever more important.

I-PEX has a large lineup of general-purpose connectors rated at 85°C and products designed for consumer devices, but to address requirements in the automotive field, we have developed a number of products that can handle high temperatures, from 105°C to 125°C, and we will continue to add to our line-up of connectors that operate reliably in high temperature environments.

Matrix of high-temperature resistance recommended connectors

Product type |

Micro-Coaxial Connectors |

RF / Coaxial Connectors< |

|||

Product Name |

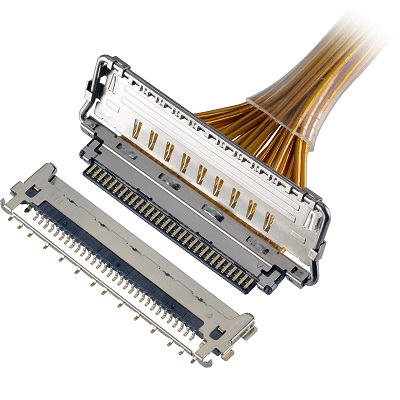

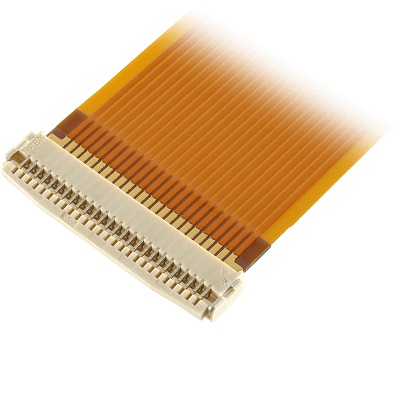

CABLINE®-VS II |

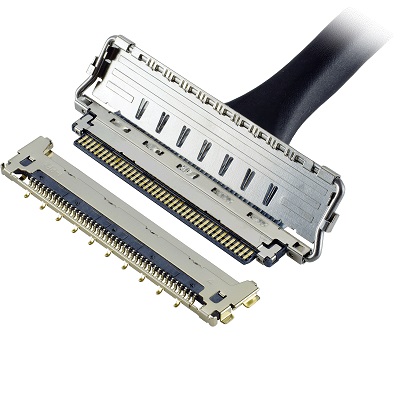

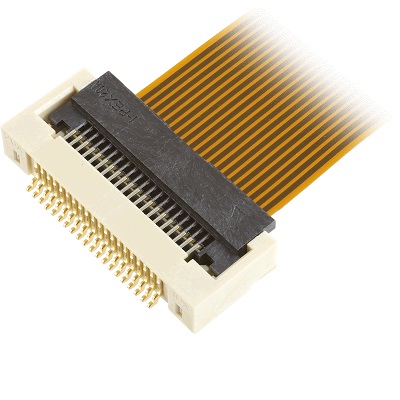

CABLINE®-CA II |

CABLINE®-CA II PLUS |

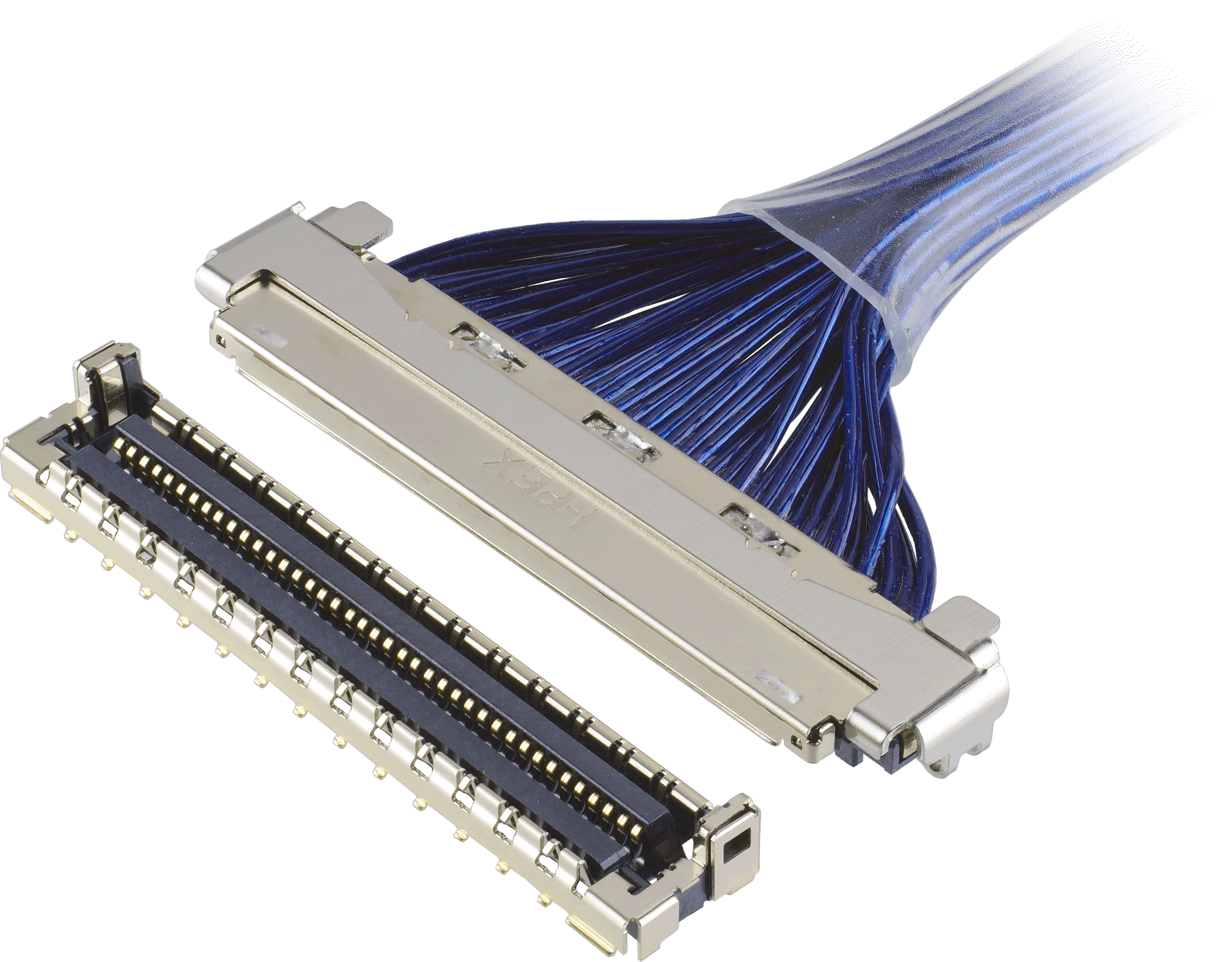

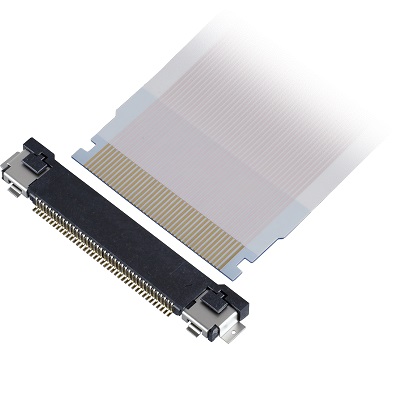

CABLINE®-UM |

MHF®-TI |

|

|

|

|

|

|

Heat resistance |

105℃ |

105℃ |

105℃ |

105℃ |

105℃ |

Pitch |

0.5 mm |

0.4 mm |

0.4 mm |

0.4 mm |

- |

Height (MAX) |

1.2 mm |

1.1 mm |

1.2 mm |

2.35 mm |

3.65 mm |

Depth |

6.7 mm |

6.2 mm |

6.7 mm |

5.0 mm |

- |

Product type |

FPC/FFC Connectors |

|||||

Product Name |

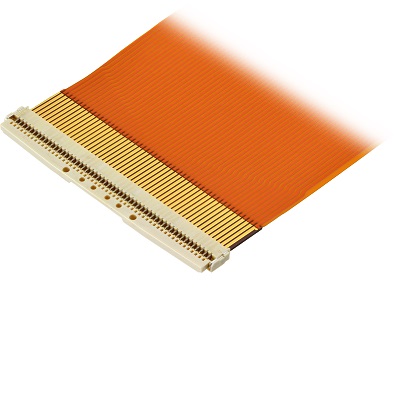

MINIFLEX® 5-BFN II |

MINIFLEX® 5-BFN II LK |

MINIFLEX® 5-FF |

EVAFLEX® 5-VS Type CH |

EVAFLEX® 5-SE-G VT |

EVAFLEX® 5-SE |

|

|

|

|

|

|

|

Heat resistance |

125℃ |

125℃ |

125℃* |

105℃ |

125℃ |

FFC:85℃

|

Pitch |

0.5 mm |

0.5 mm |

0.5 mm |

0.5 mm |

0.5 mm |

0.5 mm |

Height (MAX) |

1.1 mm |

1.1 mm |

2.75 mm |

2.0 mm |

6.9 mm |

2.7 mm |

Depth |

3.5 mm |

4.0 mm |

7.2 mm |

4.97 mm |

4.1 mm |

6.1 mm |

Product type |

Power Connectors / Terminals |

|||||||

Product Name |

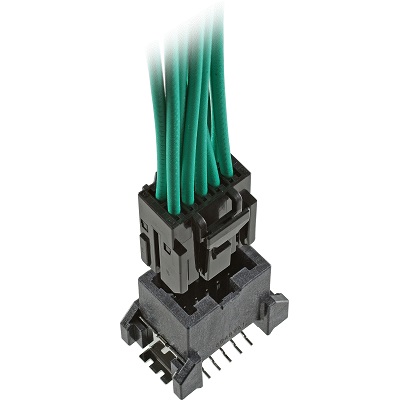

ISH® |

IARPB® |

AP-10 |

AP-TSS10,

|

||||

Type |

Horizontal |

Horizontal Type-

|

Vertical |

Wire to Wire |

Horizontal |

Vertical |

Vertical |

Vertical |

|

|

|

|

|

|

|

||

Heat resistance |

125℃ |

125℃ |

125℃ |

125℃ |

125℃ |

125℃ |

105℃ |

125℃ |

Pitch |

2.0 mm |

Signal: 2.0 mm

|

2.0 mm |

2.0 mm |

2.5 mm |

2.5 mm |

- |

- |

Height (MAX) |

(1 row) 7.4 mm

|

13.6 mm |

20.75 mm |

(1 row) 8.0 mm

|

(2/3/4/5P) 3.5 mm

|

8.7 mm |

13.6 ~ 16.1 mm

|

8.0 mm |

(*Only Specified Products)

Features of I-PEX high-temperature connectors

I-PEX provides high-temperature-resistant connectors engineered to withstand harsh thermal environments, leveraging decades of development experience and proprietary design technology. The connectors are designed to maintain stable electrical and mechanical performance even in applications requiring continuous operation at elevated temperatures up to 125°C, delivering high performance under harsh operating conditions such as those found in automotive and industrial equipment.

1) Material Selection

I-PEX selects materials with excellent workability, dielectric properties, and thermal conductivity, as well as stress relaxation characteristics that stabilize spring characteristics even in high-temperature use environments, and materials that can ensure consistent contact. Most of our products are made of phosphor bronze contact material, but we also use alloy for high-temperature products, which is a stronger material without sacrificing the high electrical and thermal conductivity inherent in copper. (Except IARPB/AP-TSS10/AP-LT10).

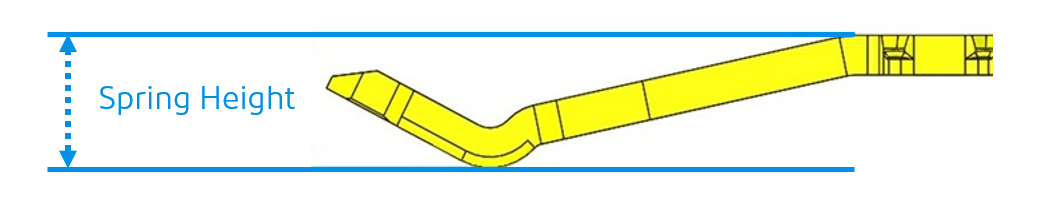

2) Design

To ensure stable electrical contact, a certain level of contact pressure is required between the contact and the mating component is indispensable. We use high-temperature-resistant metallic component for the contact elements and design them in a spring configuration, enabling the structure to maintain optimal contact force over an extended period. In particular, even under conditions involving repeated mating cycles of the connector or stress relaxation caused by temperature changes, the spring characteristics are optimized in the design stage to ensure that the specified contact force is maintained. This design ensures reliable contact performance even under harsh operating conditions.

3) Reliability Test

By employing heat-resistant materials and design that optimizes spring characteristics, thermal displacement is effectively suppressed, ensuring stable contact reliability. As a result, I-PEX products are capable of maintaining consistent performance even in high-temperature environments of up to 125 °C.

We have conducted demanding tests required for automotive applications, including temperature cycling (–55 °C to +125 °C, 100 cycles) and high-temperature endurance (125 °C for 1,000 hours), and verified that no abnormalities were observed.

※Please note that test conditions differ for each connector. Detailed evaluation and test reports for each item can be accessed through the link below.

| CABLINE®-VS II | TR-17060-06EN |

| CABLINE®-CA II | TR-15103-07EN |

| CABLINE®-CA II PLUS | TR-16075-02EN |

| CABLINE®-UM | TR-18067-09EN |

| MHF®-TI | TR-20007-03EN |

| MINIFLEX® 5-BFN II | TR-12124-06EN |

| MINIFLEX® 5-BFN II LK | TR-14132-07EN |

| MINIFLEX® 5-FF | TR-14129-08EN |

| EVAFLEX® 5-VS Type CH | TR-16039-04EN |

| EVAFLEX® 5-SE-G VT | TR-17100-03EN |

| EVAFLEX® 5-SE | TR-10048-10EN |

| ISH® Horizontal | Microsoft Word - STR-23002 ISH CONNECTOR(NORMAL LOCK) TestReport_Rev.0 |

| ISH® Horizontal Type-Hybrid | Microsoft Word - STR-23015_ISH HYBRID CONNECTOR(NORMAL LOCK)_TestReport_Rev.0 |

| ISH® Vertical | Microsoft Word - STR-23004 ISH・ISHV CONNECTOR LV214Test Report Rev.0 |

| ISH® Wire to Wire | Microsoft Word - STR-23003_ISH INLINE CONNECTER_TestReport_Rev.0 |

| IARPB® Horizontal | TR-25025-02EN(STR-24002-02EN) |

| IARPB® Vertical |

| AP-10 | TR-19063-04EN |

| AP-TSS10 AP-LT10 |

TR-23036-02EN |

Reliability Test Facilities

I-PEX has introduced various high-temperature test facilities to assess the durability and reliability of connectors under elevated temperatures. It is possible to conduct assessments under severe usage conditions, such as temperature-induced performance changes, material aging, and the stability of contact resistance.

|

Rapid-Rate Thermal Cycle Chamber  |

Thermal shock chamber  |

|

Compact thermal shock chamber  |

Contact resistance measurement system  |

By utilizing these facilities, reliability evaluation tests can be conducted in compliance with various international standards, including MIL and IEC specifications. These tests support not only quality assurance of mass-produced products but also design verification during the development of new products.

Overview

In response to the keyword of “high-temperature resistance,” I-PEX offers a wide range of connectors, providing a lineup of products that maintain stable electrical connection performance even under high-temperature environments. We will continue to advance our integrated development process combining —material research, thermal analysis, and evaluation methodologies—to meet the stringent demands of high-temperature environments and provide strong support for our customers’ needs.