RF Connectors

Contents

- 1. Compact Size and High Density

- 2. High Frequency and Data Rates

- 3. Superior EMC Performance

- 4. High Design Flexibility

- 5. Robust Design with Integrated Locking Features

- 6. Key Industry Standards

- 7. Consistent Performance with i-Fit® Technology

- 8. MHF Switch Products for Antenna Testing

- 9. Available Accessories

- 10. PCB Stack Up Optimization Services

1. Compact Size and High Density

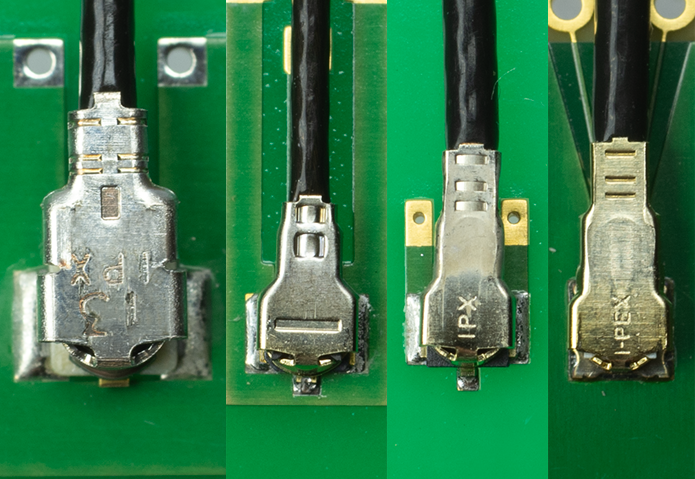

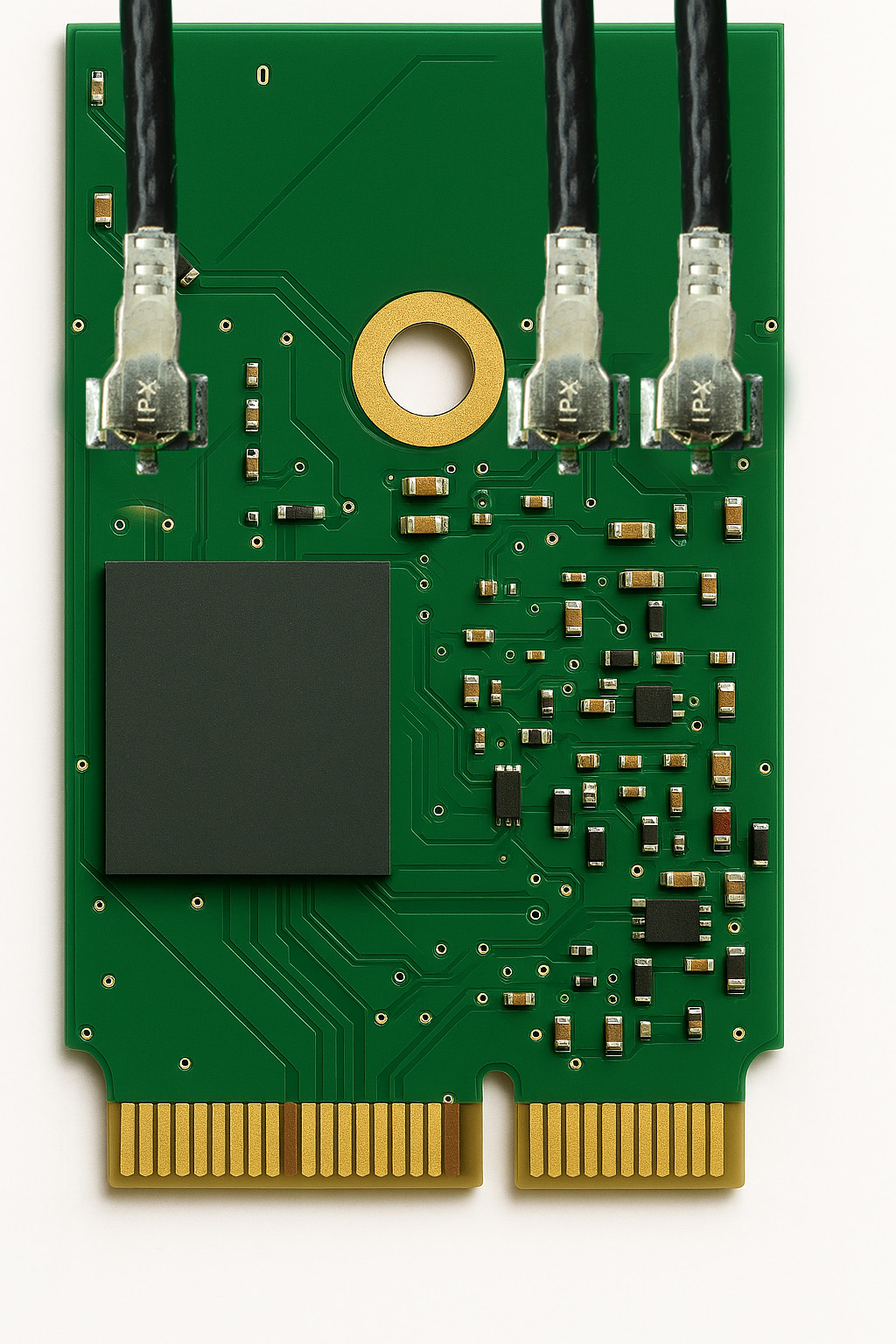

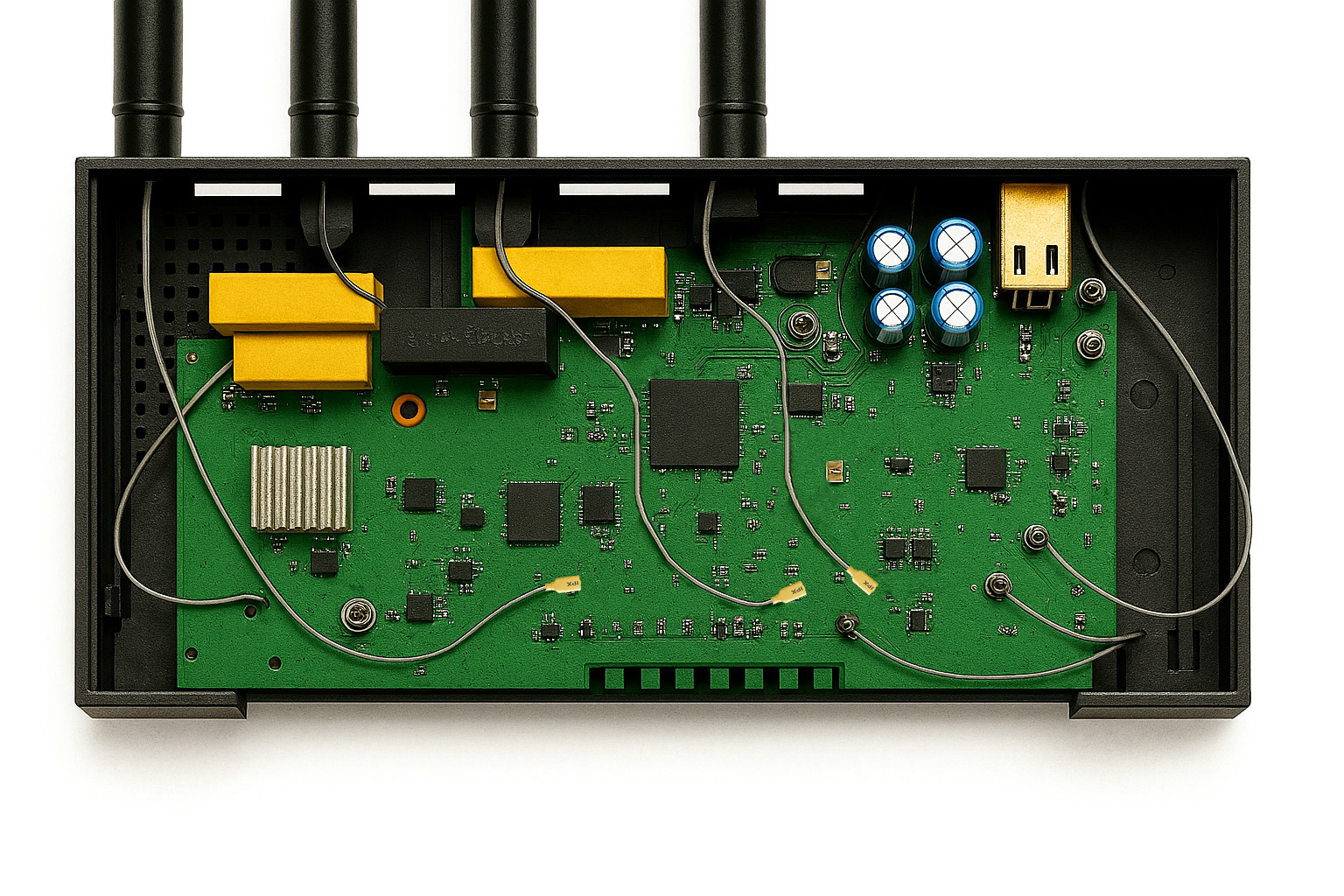

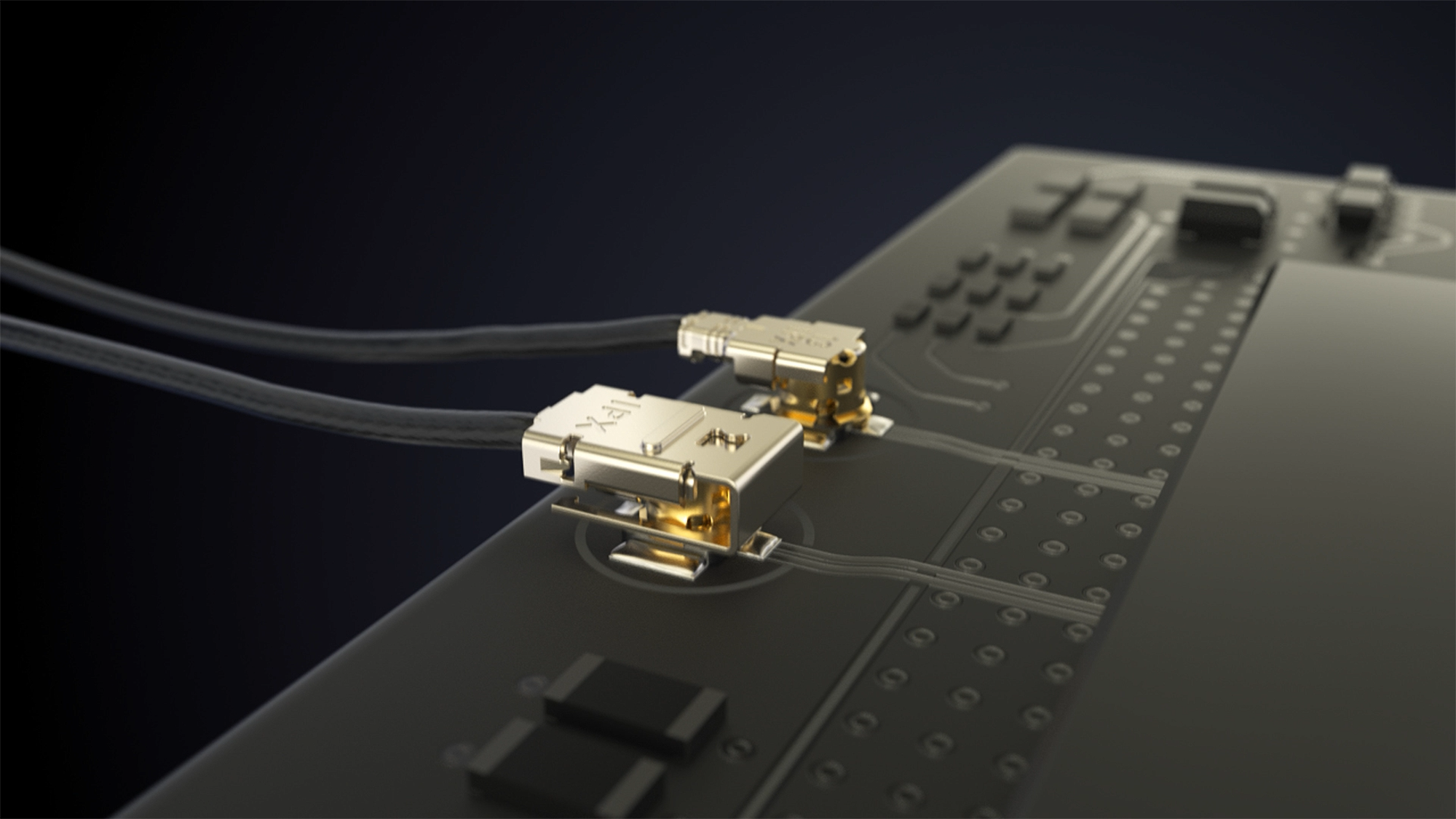

MHF Series connectors from I-PEX are ultra-miniature, low profile and light weight RF connectors that are typically used for Antenna connectivity in the latest smart phones, Tablet PCs and Notebook PCs etc. Smallest MHF connector takes up only 4 sq. mm of PCB area and availability of multiple stack up heights from 1 mm up to 3.65 mm typical provides design flexibility in RF systems with antennas for a variety of communication standards like Bluetooth, Wi-Fi and GSM etc. Connectors with integrated locking feature is useful in high vibration and shock environments and eliminates the need for separate external locks in design, saving board space and cost.

|

|

|

Learn more: Compact Size and High Density

2. High Frequency and Data Rates

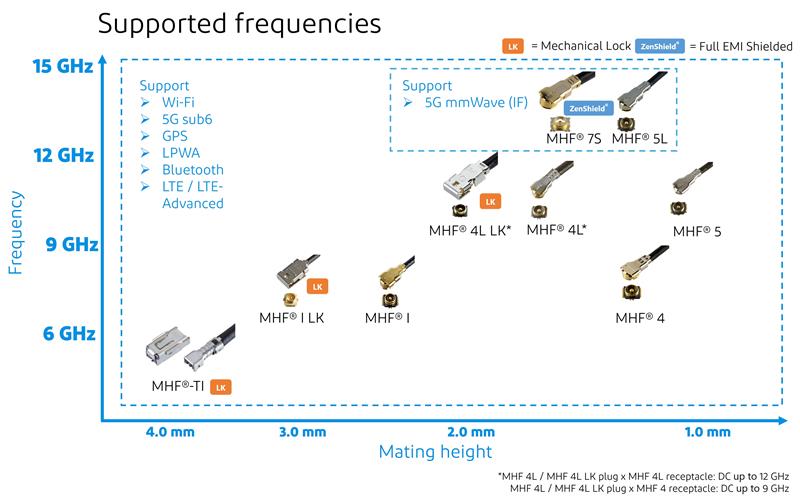

MHF Series connectors can support industry standard frequency bands from DC to 15 GHz enabling high speed wireless systems. Multiple MHF connectors can be used to successfully implement MIMO (Multiple Input, Multiple Output) systems that use multiple transmitting and receiving antennas to increase the capacity of wireless links providing benefits like higher data rates and better spectral efficiency enabling gigabit class connections. With ultra small size, mechanical locking and full EMI shielding, these connectors address unique challenges in implementation of MIMO functions in compact, portable 5G systems like limited space, isolation and coupling, cross talk and signal interference. High speed wireless systems using MHF series antenna connectors are able to deliver their full data rate potential, and the signal quality including high Signal to Noise Ratio, Reliability, Bit Error Rates and overall system data throughput.

|

|

|

Learn more: High Frequency and Data Rates

3. Superior EMC Performance

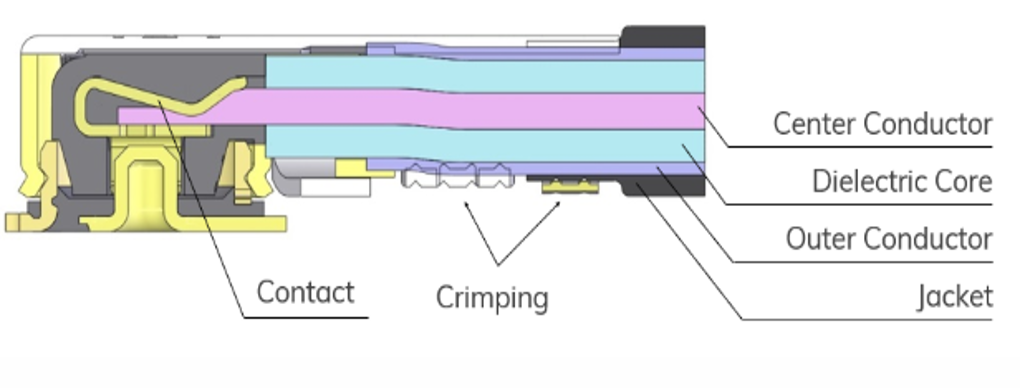

Shielding in MHF RF connectors and harnesses is vital to preserve signal integrity, maintain impedance control, reduce interference, and maximize RF efficiency. It is not just a mechanical enclosure — it’s an integral part of the electrical design that sustains high data rates and reliable antenna performance. Idea is to minimize external EMI/ RFI, prevent cross talk and maintain the impedance consistency, thereby reducing the noise and maintaining a higher Signal-to-Noise Ratio (SNR). Unique Shielded design of MHF® 7S series connectors reduces the EMI noise and offers excellent EMC performance in 5G mm wave applications.

|

|

Learn more: Superior EMC Performance

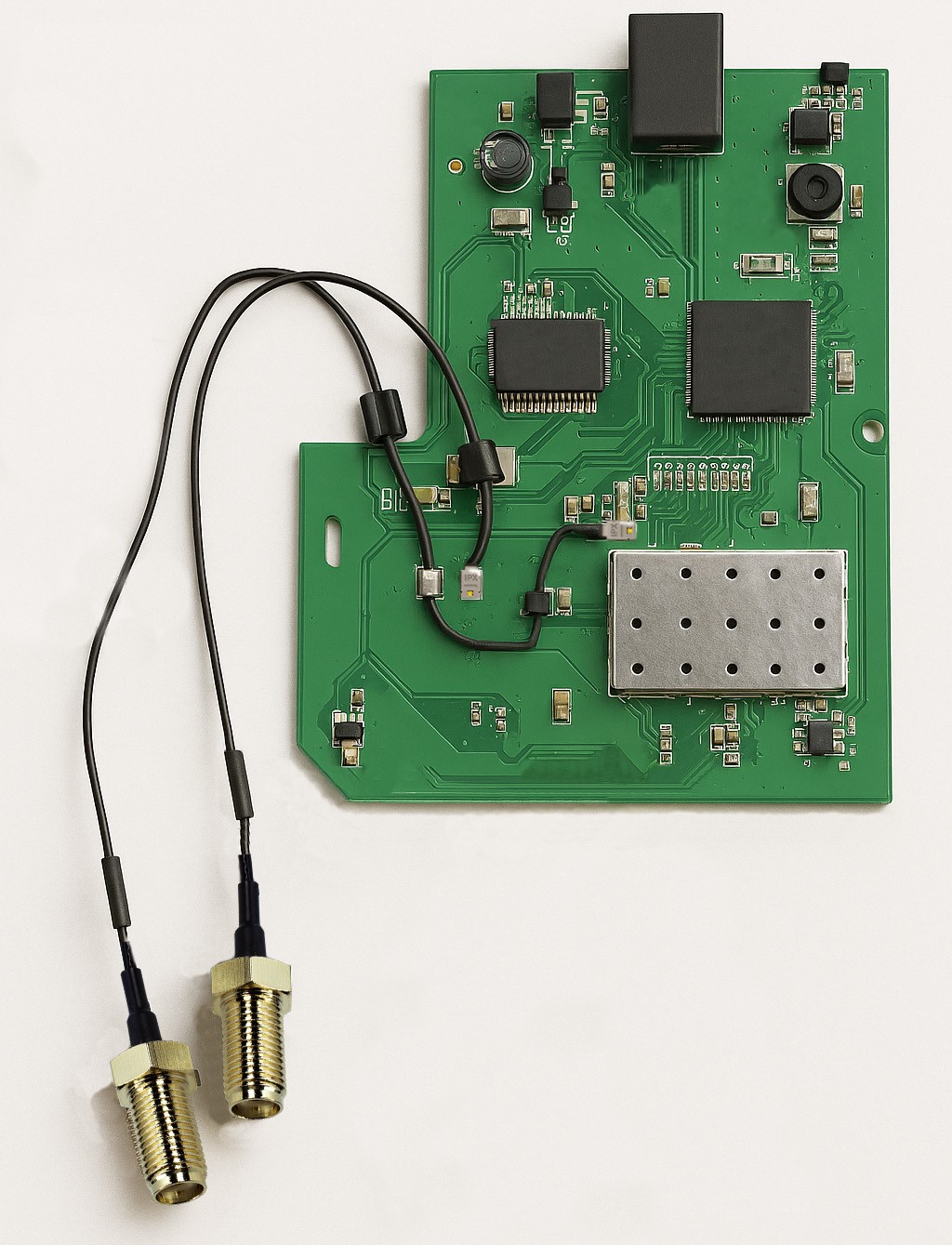

4. High Design Flexibility

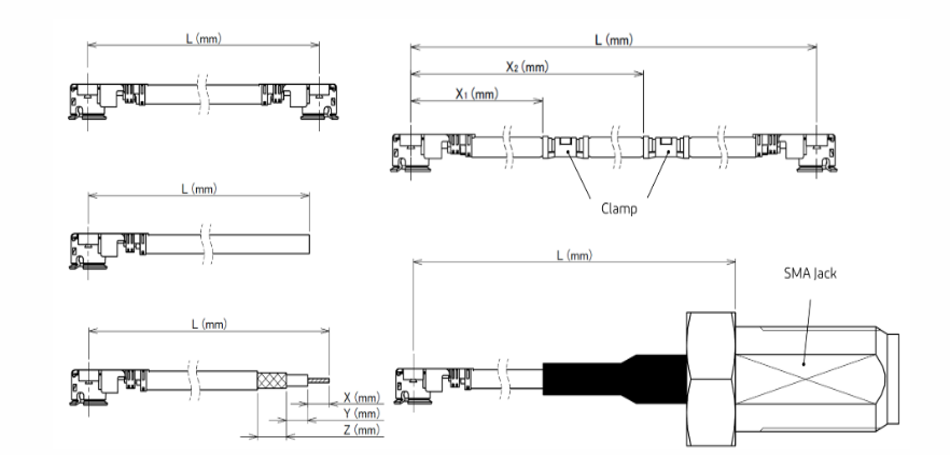

The antenna system’s effectiveness depends on how efficiently power is transferred between the radio circuitry and the antenna element. If the coaxial interconnect has high insertion loss, a significant portion of the transmitted power is dissipated as heat in the cable instead of being radiated by the antenna. Similarly, during reception, part of the weak incoming RF signal is lost before reaching the receiver front-end, reducing sensitivity and SNR. I-PEX provides a diverse range of cable diameter options designed to meet specific requirements for insertion loss, minimum bend radius and VSWR. This variety ensures flexibility in designing connectivity within wireless devices. Depending on the type of MHF connector, the outer diameters of coaxial cables vary from 0.48 mm (MHF® 5) to 3.0 mm (MHF®-TI)

Learn more: High Design Flexibility

5. Robust Design with Integrated Locking Features

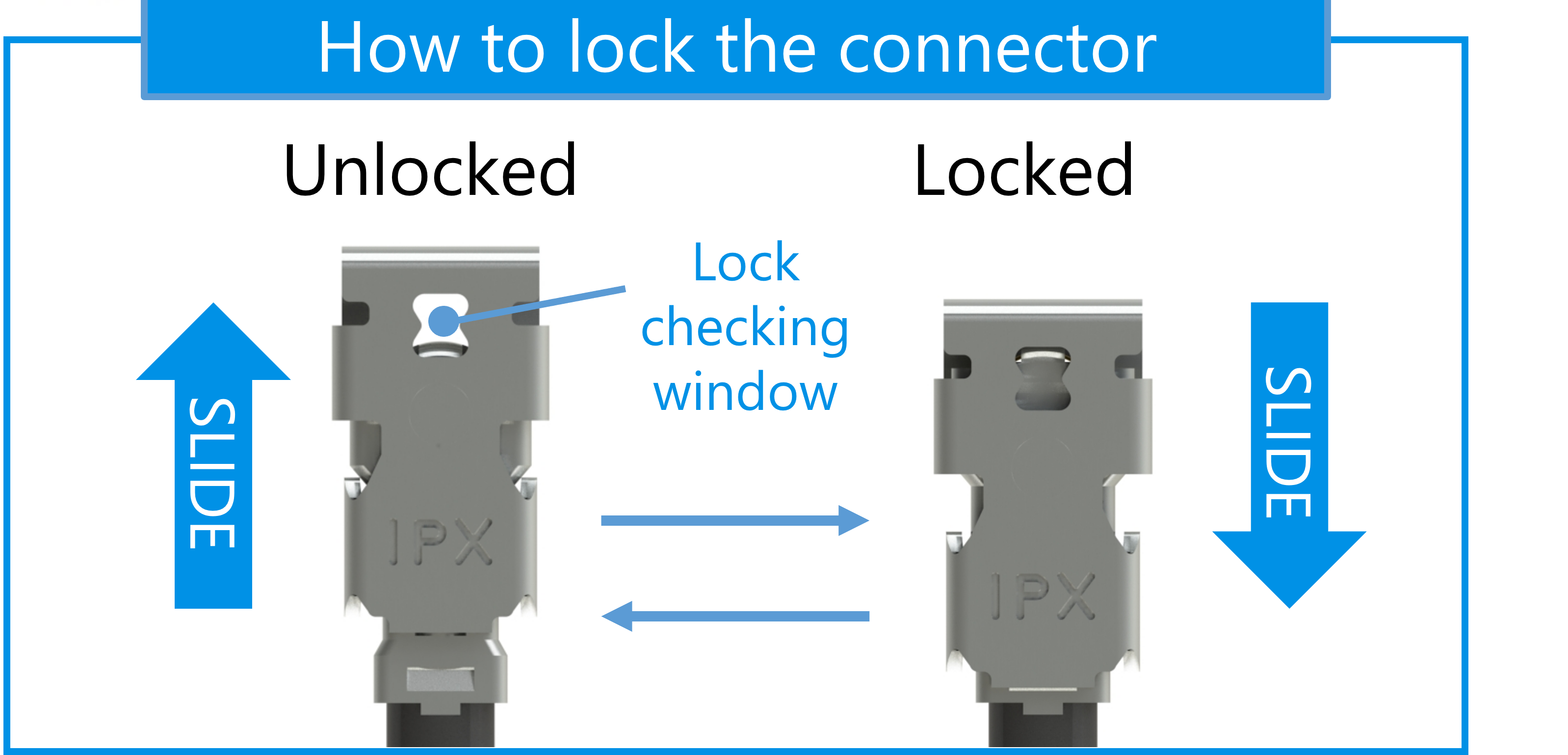

An integrated mechanical locking feature in antenna connectors plays a crucial role in ensuring reliable and stable connectivity in harsh operating environments such as those with high shock, vibration, or mechanical stress. It ensures secure, vibration-resistant, and stable electrical connections, reducing downtime, maintaining RF performance, and improving overall system reliability in demanding environments. The MHF® I LK and MHF® 4L LK enhance retention force by incorporating a locking mechanism into the standard MHF® I and MHF® 4L plugs. This innovation is particularly advantageous for applications where continuous connectivity is essential, including drones, fleet management, asset tracking, security, and personnel monitoring. With the introduction of locking functionality in two distinct sizes, MHF® I LK and MHF® 4L LK, design engineers can select options based on size and performance, thereby addressing various device and form factor challenges effectively.

|

|

|

Learn more: Robust Design with Integrated Locking Features

6. Key Industry Standards

I-PEX MHF® Series Connectors and Harnesses are standard components in a wide array of wireless devices, including tablets, notebook M.2, M2M modules, and automotive infotainment systems, and the list continues to grow as engineers find new applications for MHF solutions. As the deployment of Internet of Things (IoT) devices accelerates, the MHF® Series plays a crucial role in global wireless connectivity. To date, MHF® connector shipments have exceeded 25 billion units. I-PEX has consistently supplied a proven, reliable, cost-effective wireless design solution.

Learn more: Key Industry Standards

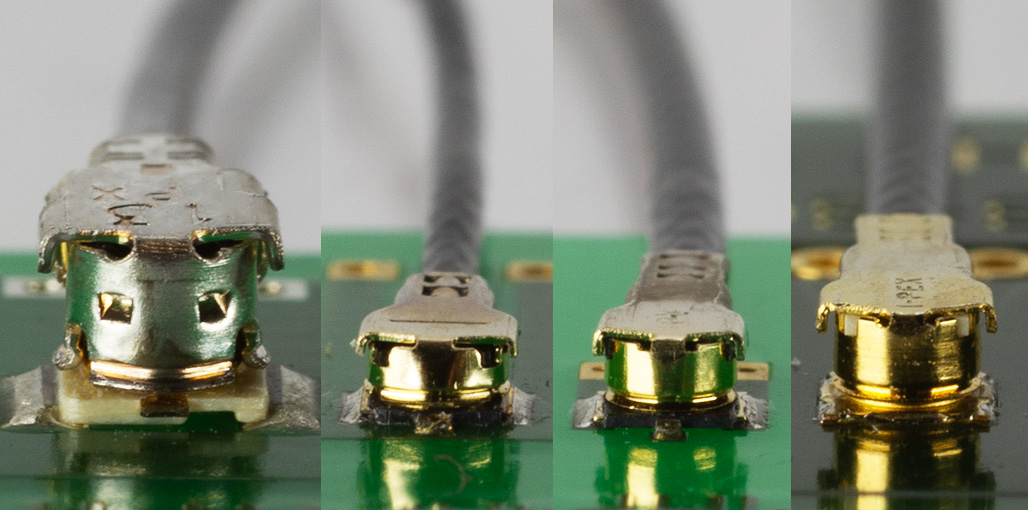

7. Consistent Performance with i-Fit® Technology

i-Fit® is unique solderless terminating technology from I-PEX to terminate the coaxial cables with MHF® series connectors. i-Fit® is the core technology that is simple, scalable and results in MHF harness assemblies with consistent performance within a tight numerical range. The harness performance repeatability enables efficient system integration due to low variability from harness to harness. In addition, it makes the mechanization of the RF connector jumper harness production relatively quick and easy, resulting in increased efficiency and high productivity. Using custom, Fully Automated Machines (FAM), I-PEX FAMs will cut, strip, crimp, check orientation, and perform mechanical and electrical checks for large production volumes.

|

|

Learn more: Consistent Performance with i-Fit® Technology

8. MHF Switch Products for Antenna Testing

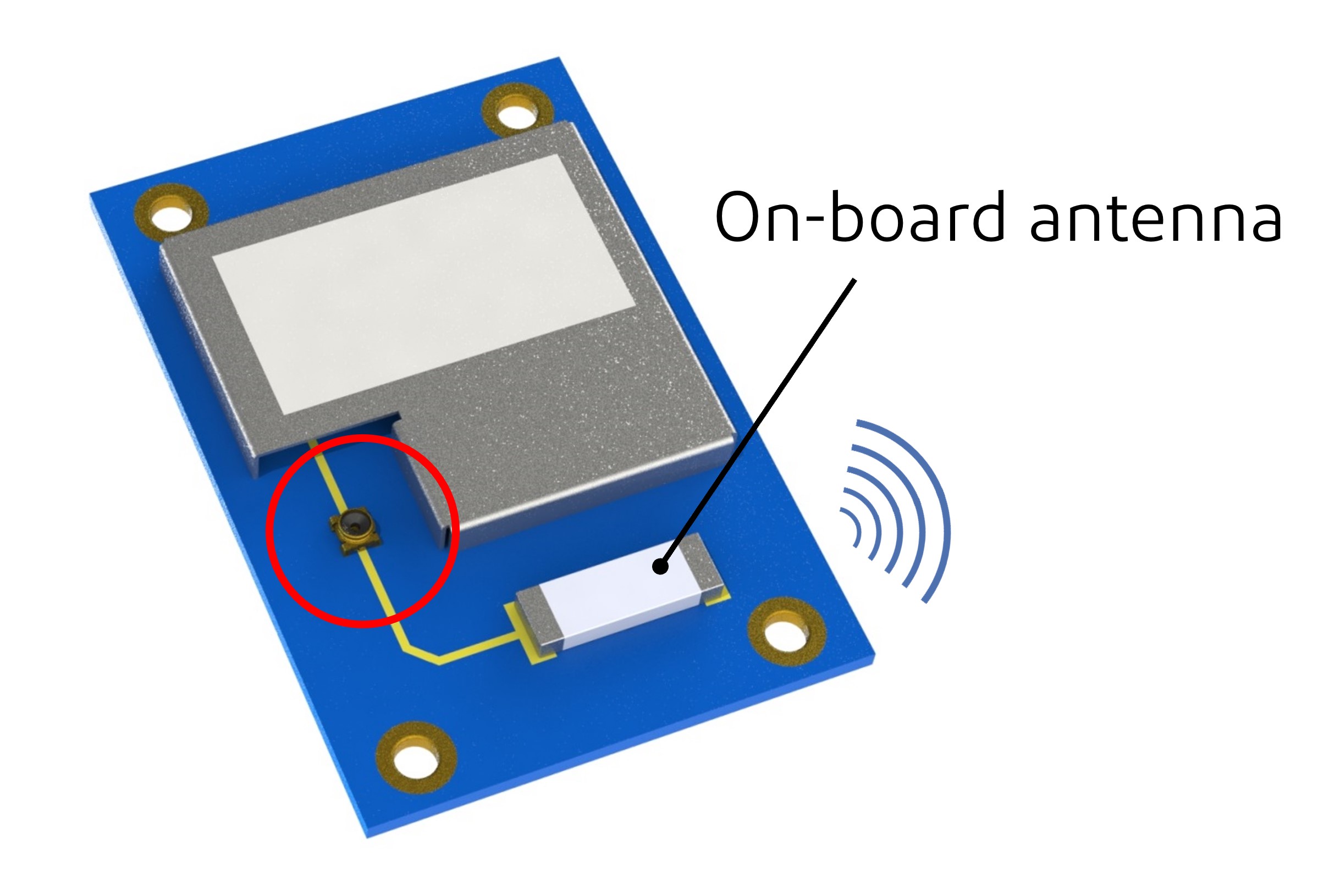

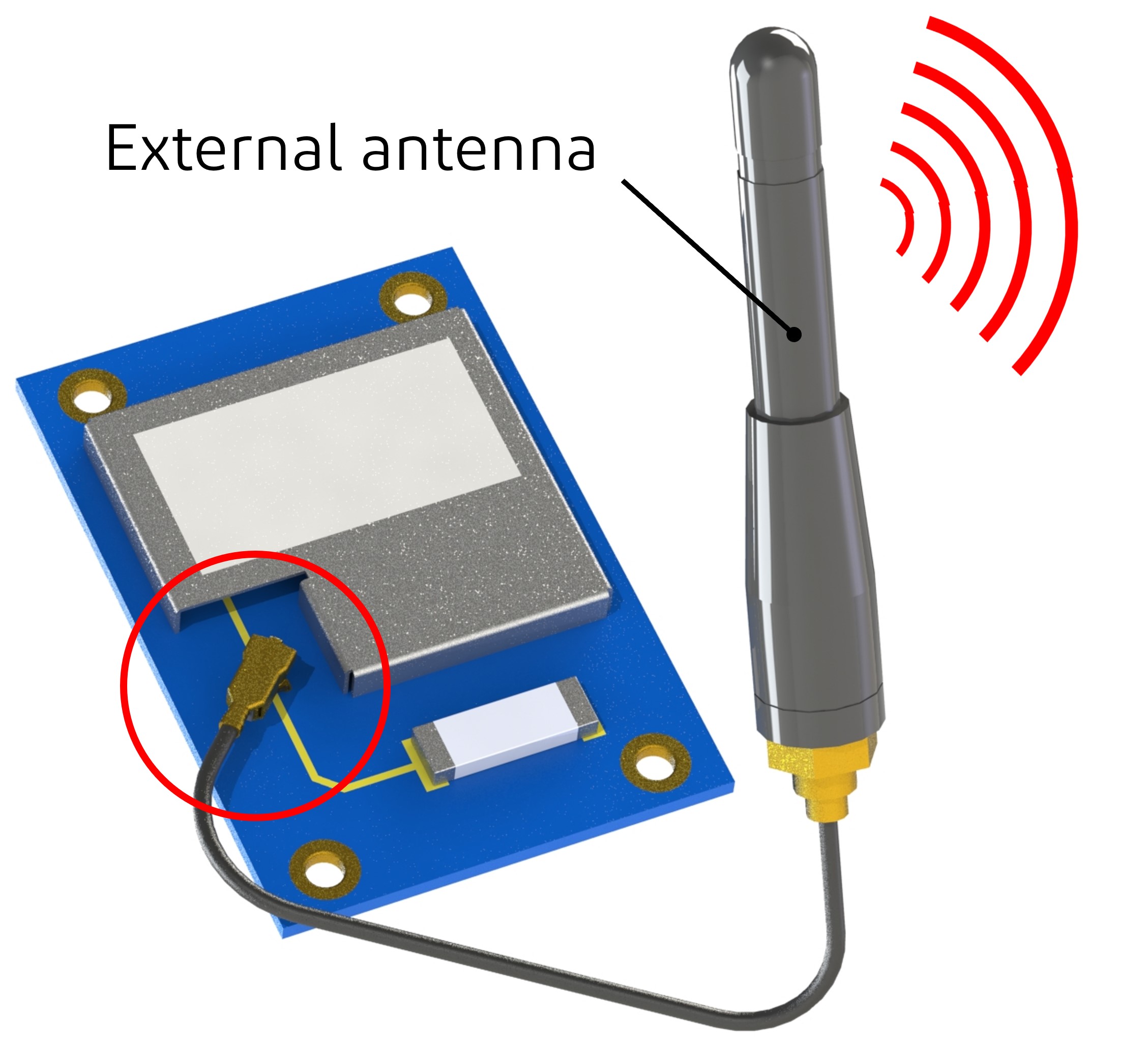

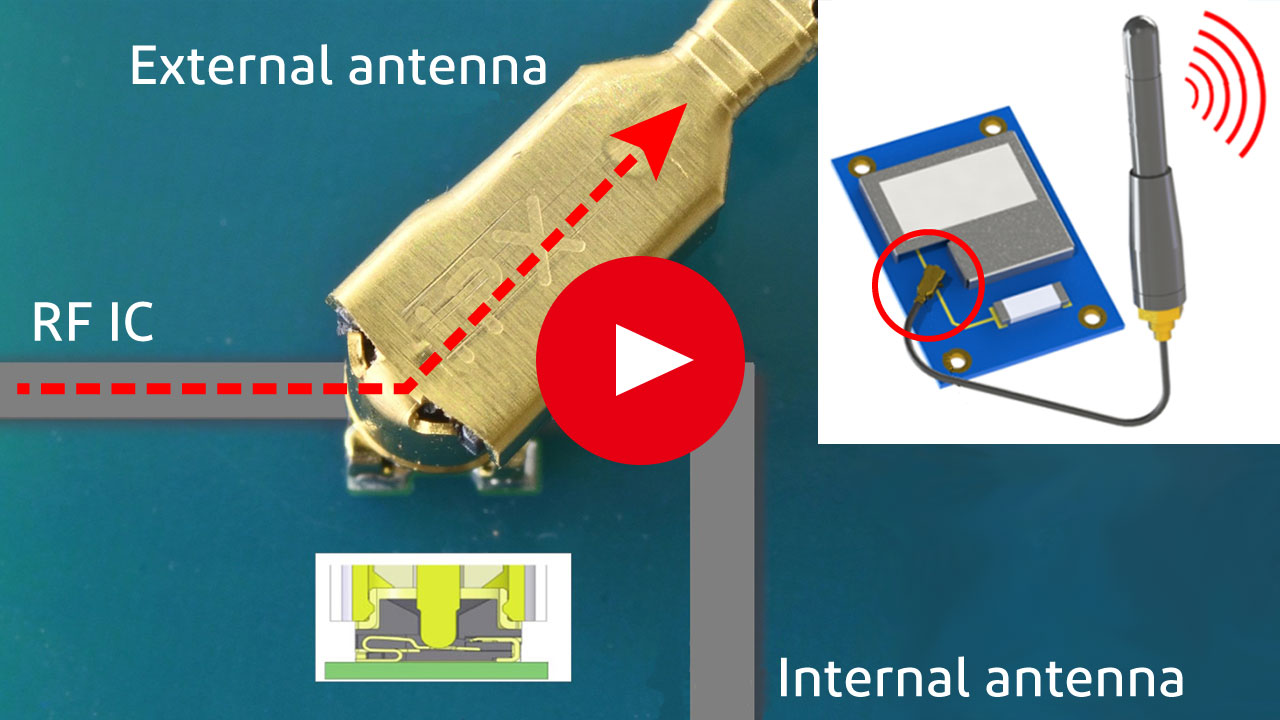

MHF®-SW23 is a compact RF switch connector with plug and receptacle components, supporting frequencies up to 11 Ghz. Its contaminant resistant design prevents any signal discontinuity even after repeated mating cycles. With low profile height of 1.3 mm (max), the switch is suitable for high density designs where vertical clearance is limited. Often used as a switch to select on-board or external antenna, MHF®-SW23 offers excellent isolation in OFF state and optimal Signal Integrity in ON state. Testing of antenna modules by using Inspection Probes also quite common application for these products.

| On-board antenna | External antenna |

|

|

|

|

MHF®-SW23 (RF switch) |

MHF®-SW23 PLUG & MHF®-SW23 |

Learn more: MHF Switch Products for Antenna Testing

9. Available Accessories

I-PEX offers MHF® accessories to support test needs from R&D to high-volume production. MHF® adapters for VNA testing, lab probes, and high-volume test probes are available. Additionally, I-PEX offers MHF® insertion and extraction tools to properly mate the plug and limit accidental damage during installation in the lab and on the production floor.

Learn more: Available Accessories

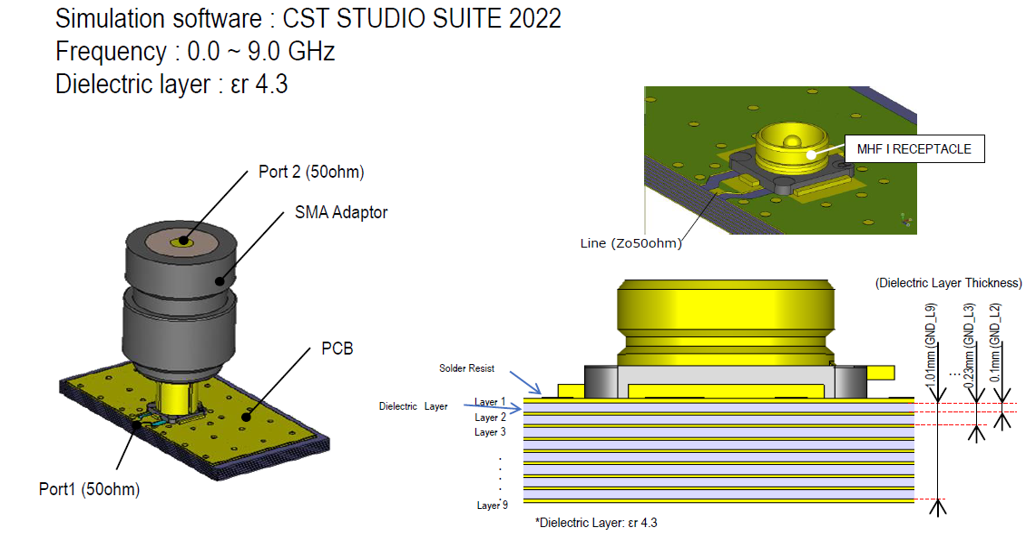

10. PCB Stack Up Optimization Services

When it comes to achieving optimal signal integrity and frequency response, PCB lay out and design is critical. By optimizing the number of layers and their stack up and geometry in board design, losses, EMI leakage, resonance and cross talk of RF signals going through MHF connectors is minimized.

Learn more: PCB Stack Up Optimization Services