Connectivity Solutions Enabling Robotic Assisted Surgery in Healthcare 4.0

Robotics and Robotic-Assisted Surgery

Modern surgical robots are a cornerstone of Healthcare 4.0, enabling surgeons to perform minimally invasive procedures with unprecedented precision and control. In robot-assisted surgery, a human surgeon operates advanced instruments mounted on robotic arms, often through tiny incisions with the help of a high-definition 3D camera. By filtering out hand tremors and scaling movements, robots like the da Vinci® system allow extremely fine maneuvers that would be challenging by hand. The benefits include reduced patient trauma, smaller scars, and faster recovery. Adoption of surgical robotics continues to grow – as of 2021, over 10 million robotic-assisted procedures had been performed worldwide (Robotic Surgery Statistics and Facts (2025)).

Connectivity and Data Needs

Surgical robotics rely on a multitude of signals and data flows. The surgeon’s console must transmit control commands and receive real-time video and sensor feedback with near-zero latency. High-bandwidth connections carry HD video from the surgical site, while control links convey precise movements. Any lag or interference could jeopardize the procedure, so EMI-shielded cable assemblies for surgical robots are used to maintain signal integrity amidst the numerous electrical devices in an operating room. Designers therefore use shielded micro-coaxial connectors for noise-free imaging feeds, and robust power interconnects to deliver instantaneous motor drive signals.

Next-generation surgical systems are also exploring network connectivity (even 5G) to enable remote telesurgery, which demands extremely reliable data transmission.

Connector Design Challenges

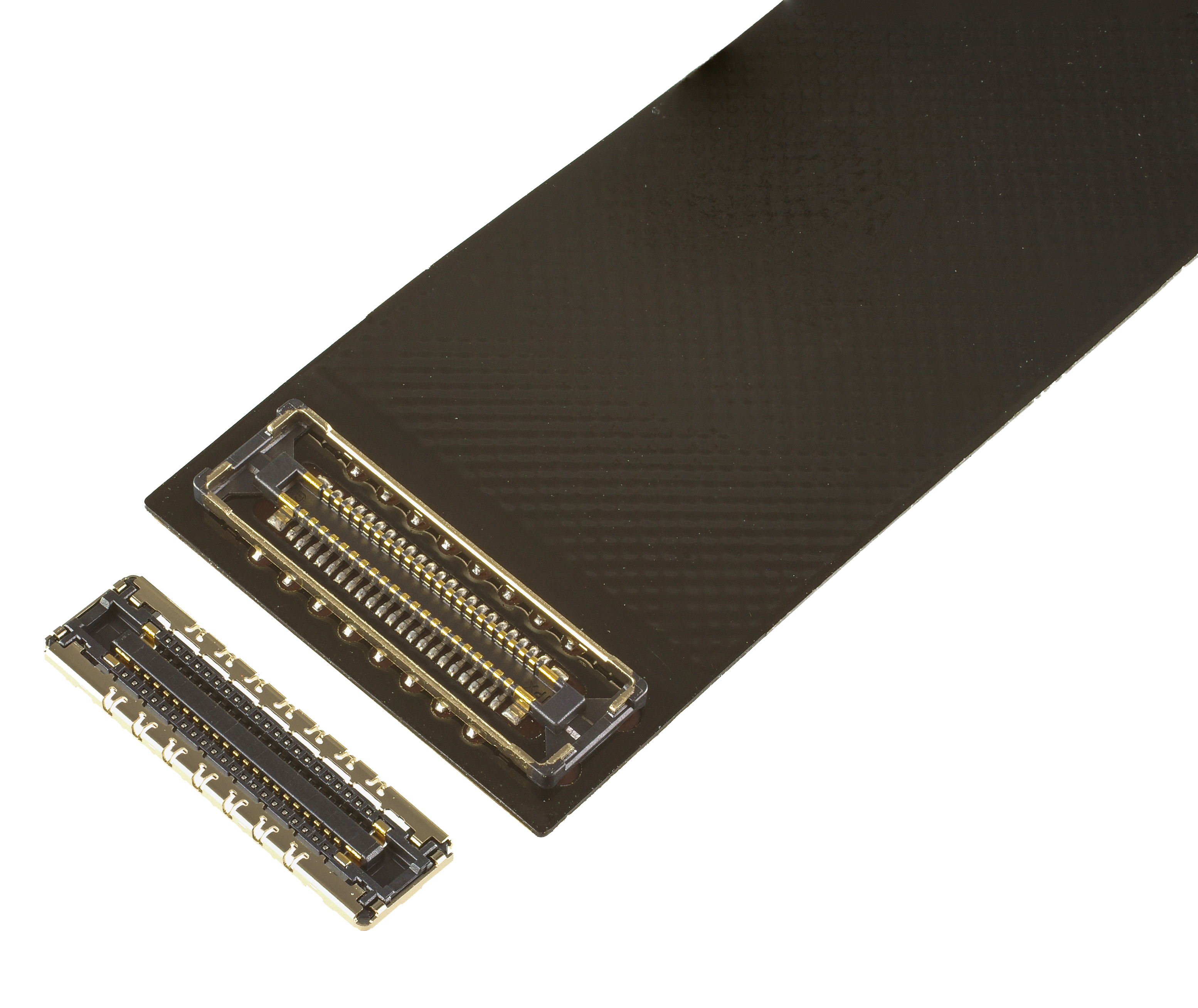

Robotics in medicine presents unique connector requirements. Each robotic arm or tool interface may house multiple connectors for power, data, imaging, and sometimes fluidics. These connectors must be high-speed (to support HD imaging and high-frequency sensor data) and high-reliability under motion. Vibration, motion, and electrical noise are constant factors – connectors like I-PEX CABLINE® micro-coaxial series address this by offering fully shielded, high-data-rate links with secure latching, minimizing the chance of disconnection or EMI issues. Internal board-to-board connectors such as I-PEX NOVASTACK® can link control boards within a compact robot joint, carrying gigabit signals between modules.

Frequent Mating and Sterilization

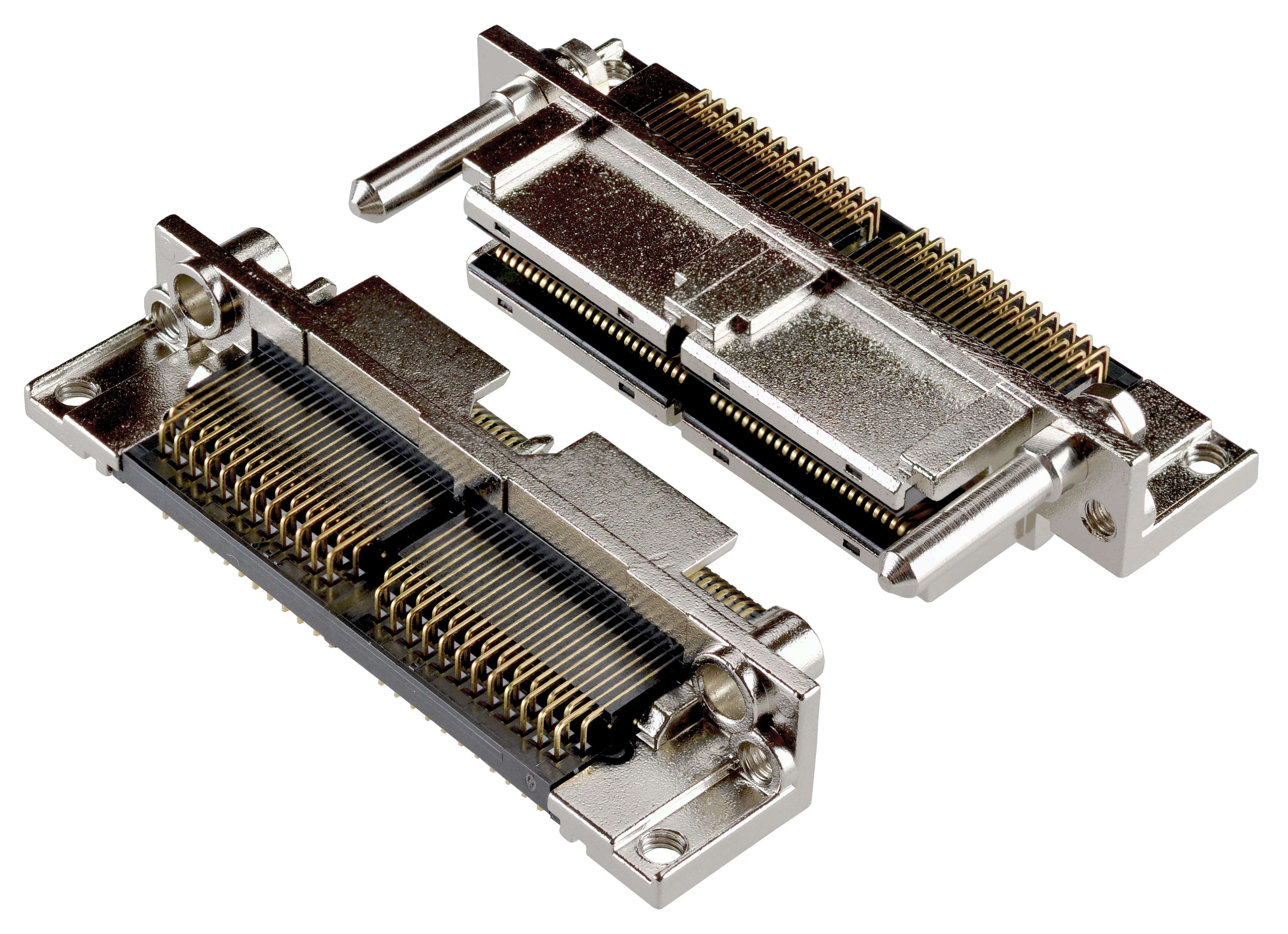

Another challenge is the frequent mating cycles at the interfaces where surgical instruments or accessories attach to the robot. These docking connections might be engaged and disengaged for every procedure or instrument change. I/O connectors designed for robotics, like the I-PEX MINIDOCK™family, use rugged housings and alignment features (guide pins) to ensure quick, error-proof mating even when a surgeon or nurse swaps tools mid-surgery. With support for thousands of mating cycles, such connectors can withstand daily use.

Additionally, they are built to endure sterilization processes – either by being autoclavable themselves or by supporting the use of sterile disposable covers on the robotic instruments. Connectors that survive steam autoclaving and harsh disinfection (using materials like surgical-grade stainless steel or high-temperature polymers) are critical in the surgical environment.

In summary, robotic-assisted surgery demands connector solutions that deliver high-bandwidth performance and absolute reliability. From EMI-shielded high-speed links for cameras and sensors to heavy-duty docking connectors for surgical tools, the right interconnects ensure that surgical robots operate flawlessly. By utilizing specialized connector families such as CABLINE®, NOVASTACK®, and MINIDOCK™, design engineers can build robotic surgical systems that provide surgeons with seamless control and patients with safer, minimally invasive outcomes.