Jacketing and Bundling | Micro-Coaxial/Twinaxial Connectors

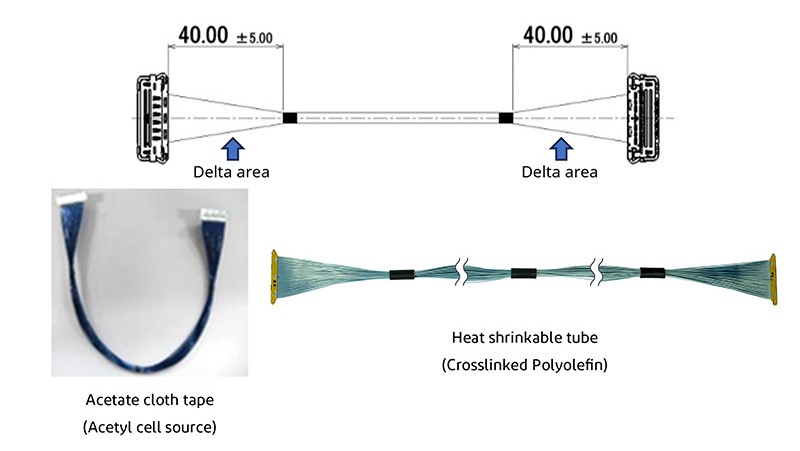

Four different types of Outer Tapes or Jackets are offered for High Speed Cable Harnesses for increased routing and placement flexibility in designs. In Type 1 multipoint bundle style, Acetate Cloth type or Heat Shrinkable Tube Tape is wrapped around the cables at multiple points bundling the cables only at certain sections as shown in Figure 1 below :

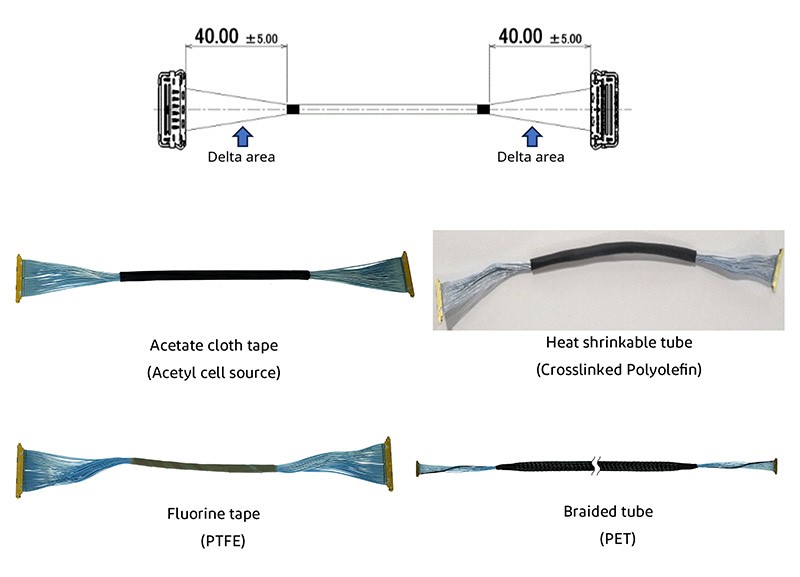

In Type 2 jacketing style, Acetate Cloth type of Heat Shrinkable Tube Tape is wrapped around most of the cables to form the bundle except for the delta area near the connectors as shown in Figure 2 below.

Available materials for Type 2 jacketing include Acetate cloth tape, Flourine tape (PTFE), Heat shrinkable tube and Braided tube (PET) types.

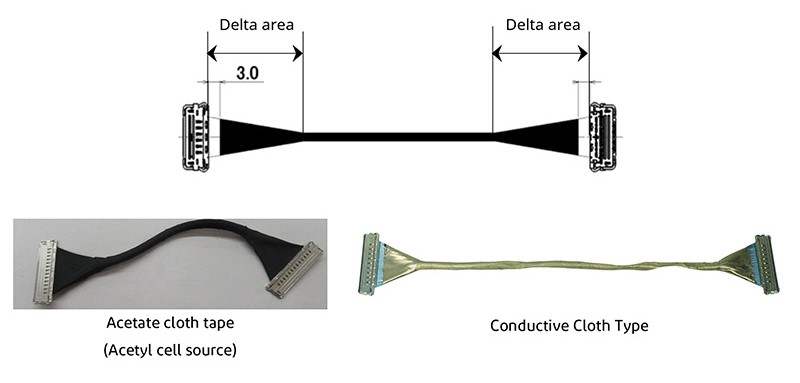

Type 3-A Bundle wraps and bundles almost the entire set of cables in the harness leaving the gap of only 3mm uncovered from each connector as shown in Figure 3 below.

Type 3-B Bundle wraps and bundles the complete length of cables in the harness with the tape put on the end of each connector as shown in Figure 4 below.

Both Acetate and Conductive Cloth type materials are used in the Type 3-B Bundle Style.

Type 4 is Flat Bundle Type Taping Style in which Laminated Tape (PET) or Acetate Cloth Tape is attached from top and bottom side of cable with a gap of 3.0 mm from the end of each connector. Figure 4 shows the Type 4 Flat Bundle Cable Harnesses below:

What is a Micro-Coaxial/Twinaxial Connector?

- 1) Micro-Coaxial Cable Harness

- 2) Twinaxial Cable Harness

- 3) Maximum Operating Frequency

- 4) Available Real Estate For Connector

- 5) EMI Shielding and Power Signals

- 6) Minimizing the Losses

- 7) Bending, Flexing and Twisting Requirements

- 8) Pin Out Assignments

- 9) Jacketing and Bundling Types

- 10) High-Speed Protocols

- 11) Harness Manufacturing Process