What is a Twinaxial Cable Harness and why do you need it?

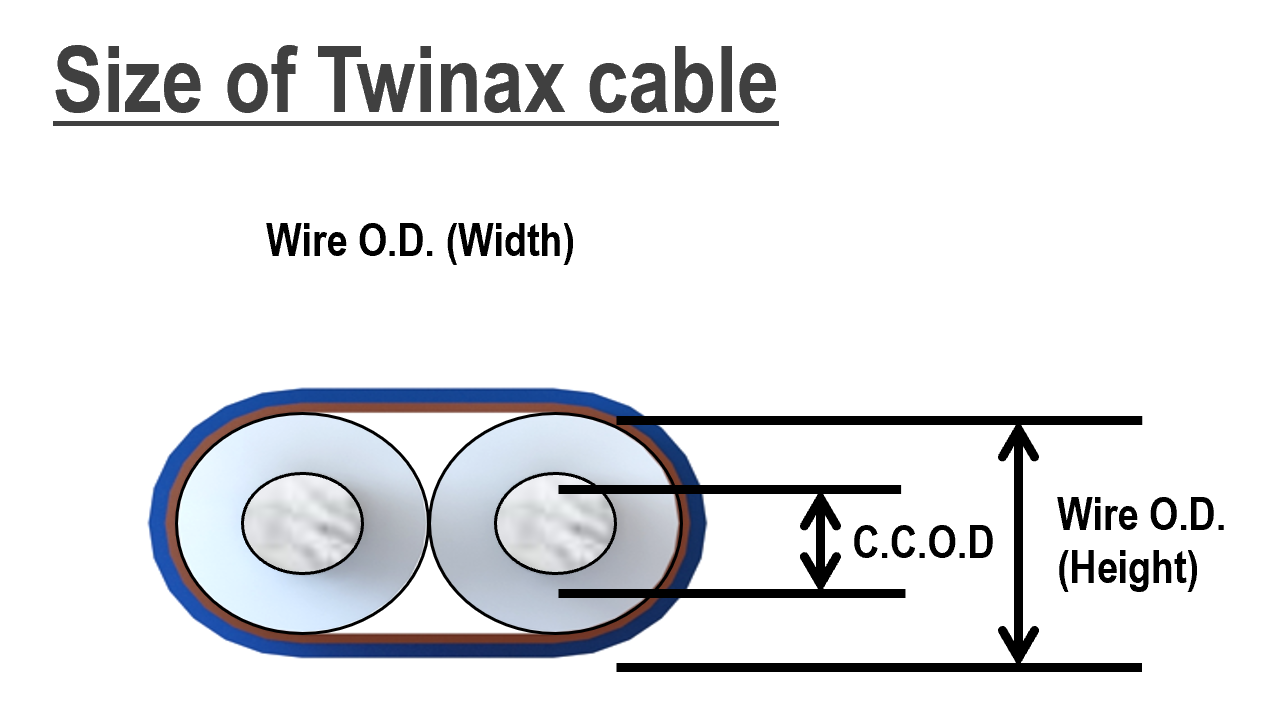

A Twinaxial cable has two center conductors typically used for differential signals. The two conductors are separated and surrounded by insualator like rubber or plastic. There is outer layer of dielectric around these conductors for insulation just like in Micro-coaxial cables. There is metallic outer conducting shield for ground return current and outer PVC type jacket. Twinaxial cables are more suitable for high speed digital data transmission that uses low voltage, low skew, tightly phase matched signals. These cables also dissipate less heat and offer lower signal losses than PCB traces and so can be used to interconnect the devices on the board. Various sizes of Twinaxial cables are available to use with I-PEX connectors based on required signal integrity performance in system.

AWG (size) |

Characteristic impedance (ohm) |

C.C.O.D : Center Conductor Outer Diameter |

Wire .O.D.

|

Color |

Rating Temperature (℃) |

#40 |

90 |

0.09 |

0.38×0.59 |

Blue |

80 |

100 |

0.09 |

0.41×0.62 |

Blue |

80 |

|

#42 |

105 |

0.075 |

0.35×0.54 |

Blue |

80 |

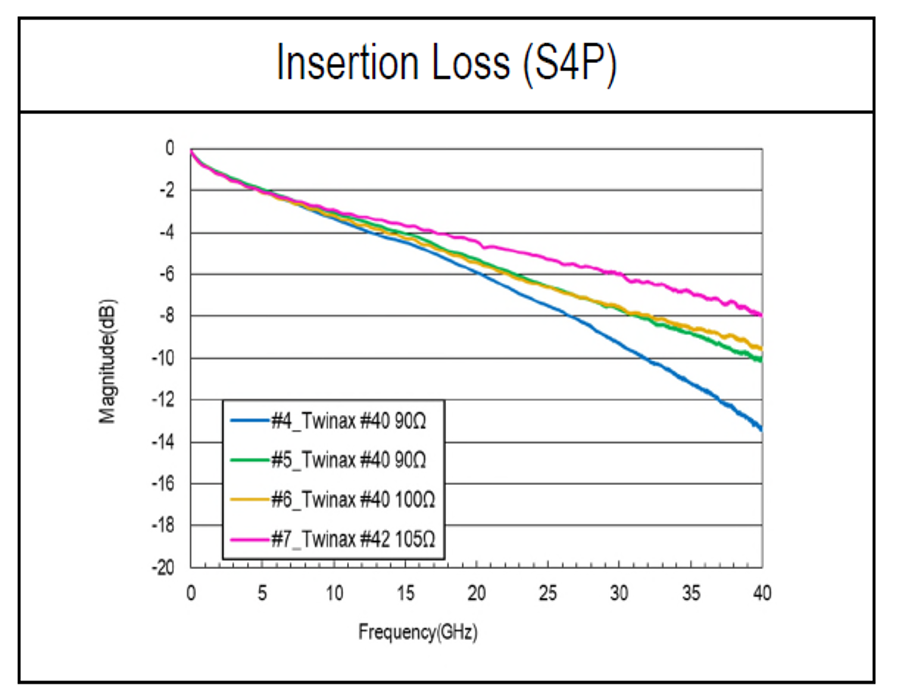

Insertion Loss performance of different sizes of twinaxial Cables is shown in the Graphs and table below.

(dB) |

10 GHz |

20 GHz |

30 GHz |

40 GHz |

*Inner Conductor Material |

|

#4 |

Twinaxial cable AWG#40 90ohm |

-3.34 |

-5.92 |

-9.29 |

-13.42 |

Sn Plated Sn-Cu Alloy |

#5 |

Twinaxial cable AWG #40 90ohm |

-3.05 |

-5.28 |

-7.68 |

-10.09 |

Tinned copper alloy |

#6 |

Twinaxial cable AWG #40 100ohm |

-3.18 |

-5.44 |

-7.58 |

-9.62 |

Tinned copper alloy |

#7 |

Twinaxial cable AWG #42 105ohm |

-2.94 |

-4.44 |

-5.98 |

-7.94 |

Silvered copper alloy |

AWG #42 cable has less loss than the AWG40 cable, but this is thought to be due to the effect of the Inner conductor plating.

Both shielded and unshielded connectors with optional mechanical lock are available for Twinaxial cable assemblies. Low speed signals traveling on the PCB traces in designs with components that are placed relatively away from each other can use the connectors with out EMI shield since there is little intererence between the signals. However, for higher frequency signals in relatively smaller, compact designs fully shielded connectors with ZenShield® and optional mechanical locking feature are offered for reliable connectivity.

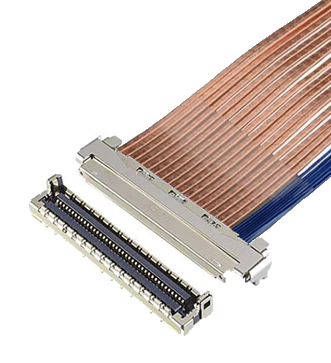

AWG 40 and 42 size Twinaxial cables can be used with CABLINE®-VS, CABLINE®-VS II, CABLINE®-CA, CABLINE®-CA II and CA II Plus and CABLINE®-UM series products to offer a complete harness solution that offers both electrical and mechanical flexibility in design with different physical sizes and loss profiles of cables used.

ZenShield® is complete 360 degree metallic shielding offered in CABLINE®-VS II, CABLINE®-CA II and CABLINE®-CA II PLUS for Twinaxial cables. With ZenShield®, EMI and switching noise is minimized for complete harness in high density, crowded PCB layouts. Similarly, mechanical locking feature is offered in CABLINE®-VS/ VS II, CABLINE®-CA and CABLINE®-CA II/ CA II PLUS series products for additional reliability and robustness in applications with high vibration and moving parts.

|

|

Figure 2. CABLINE® -CA IIP PLUS and CABLINE®-UM Series Cable Assemblies