Current Ratings and Power Pins

As modern electronics become smaller, the printed circuit boards inside the devices become highly populated with higher density than ever before. It has become more critical to deliver high power signals reliably alongside the high speed signals in a compact footprint between multiple boards without compromising the system performance. NOVASTACK® series connectors are offered in hybrid signal and power pin options in different pin counts from 10 pins to 60 pins and can handle currents up to 6 A per power pin in high power variants. These hybrid connectors save board space and cost, offer design flexibility while keeping the total heat dissipation of connector low.

NOVASTACK® 35-P is a low profile, unshielded, high heat resistent, hybrid high speed and power board to board connector with maximum current rating of up to 2 A/ power pin. NOVASTACK® 35-PH is also unshielded but a higher profile connector with current rating up to 3 A/ power pin and is available in maximum pin count of 50 pins. When it comes to shielded hybrid signal and power board to board connectors, NOVASTACK® 35-HDP is a lower profile connector with maximum current rating of 4.5 A/pin and a maximum pin count of 62 pins. While, NOVASTACK®-B is a high power variant with current rating of 6 A/pin but maximum pin count is limited to total of 8 pins only.

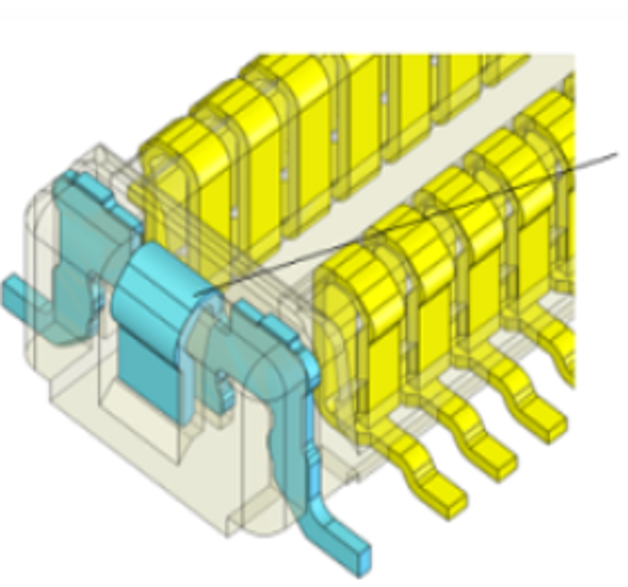

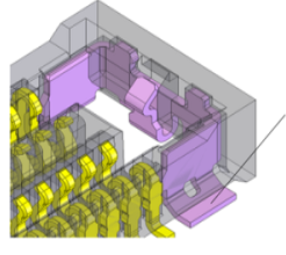

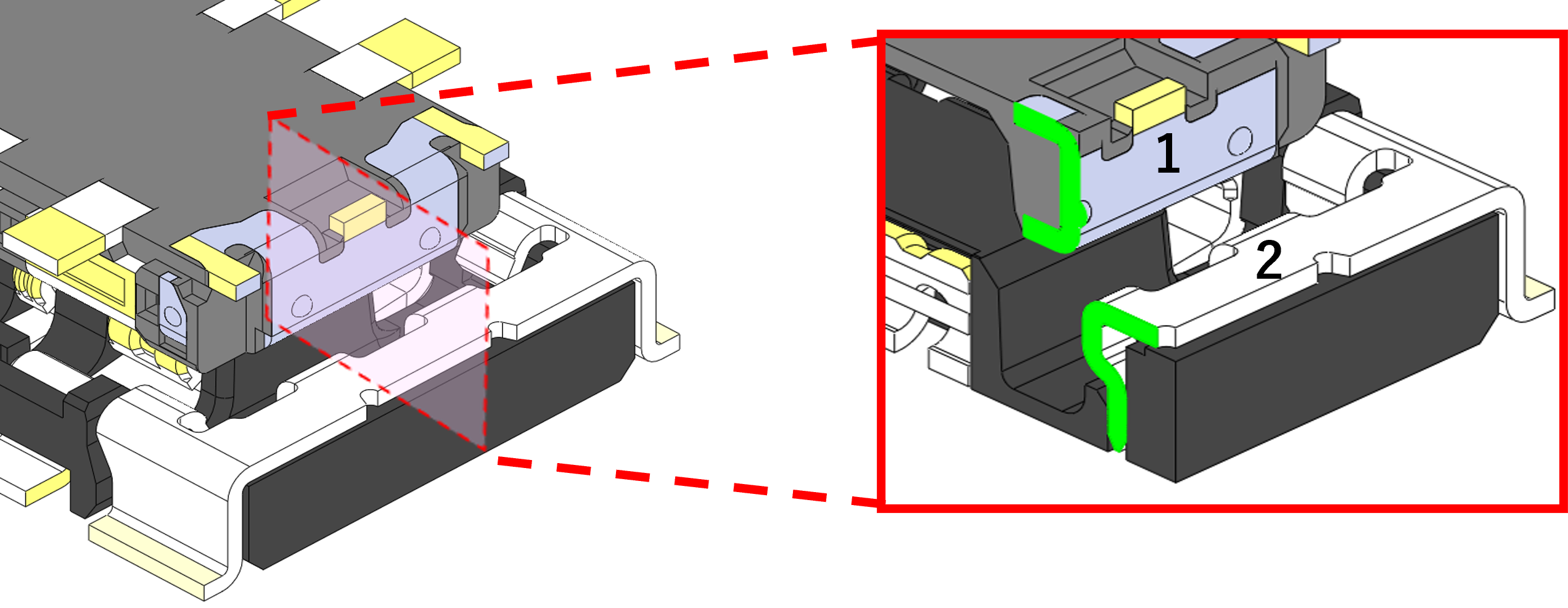

All power pins of plugs and receptacles in NOVASTACK® connectors are reinforced with metal for additional current handling. The Hold Down feature of these connectors allows the use of reinforced metal power pins, one pin on each side of plug and receptacle to be used for high power signals as shown in the Figure below. At the same time, these reinforced pins offer high retention force for mated pins and prevent half mating of plug and receptacle. Metal Hold Down pins in both plugs and receptacles of NOVASTACK®-B connectors also offer high reliability for repeated connections.

|

Plug metal reinforcement (Hold down) |

|

Receptacle metal reinforcement (Hold down) |

| Metal hold down to reduce connector damage during mating process 1. Plug Hold down 2. Receptacle Hold down

|

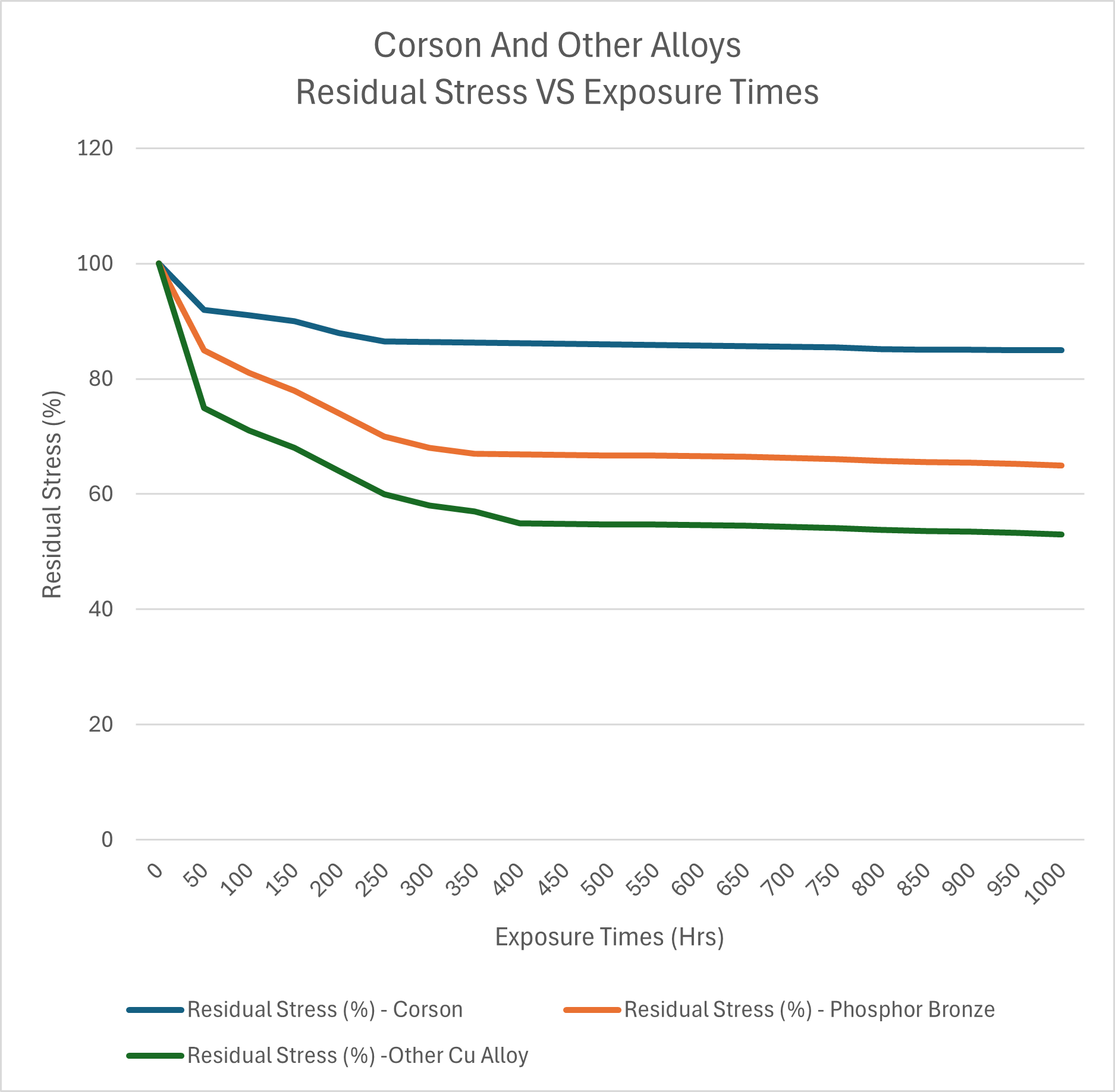

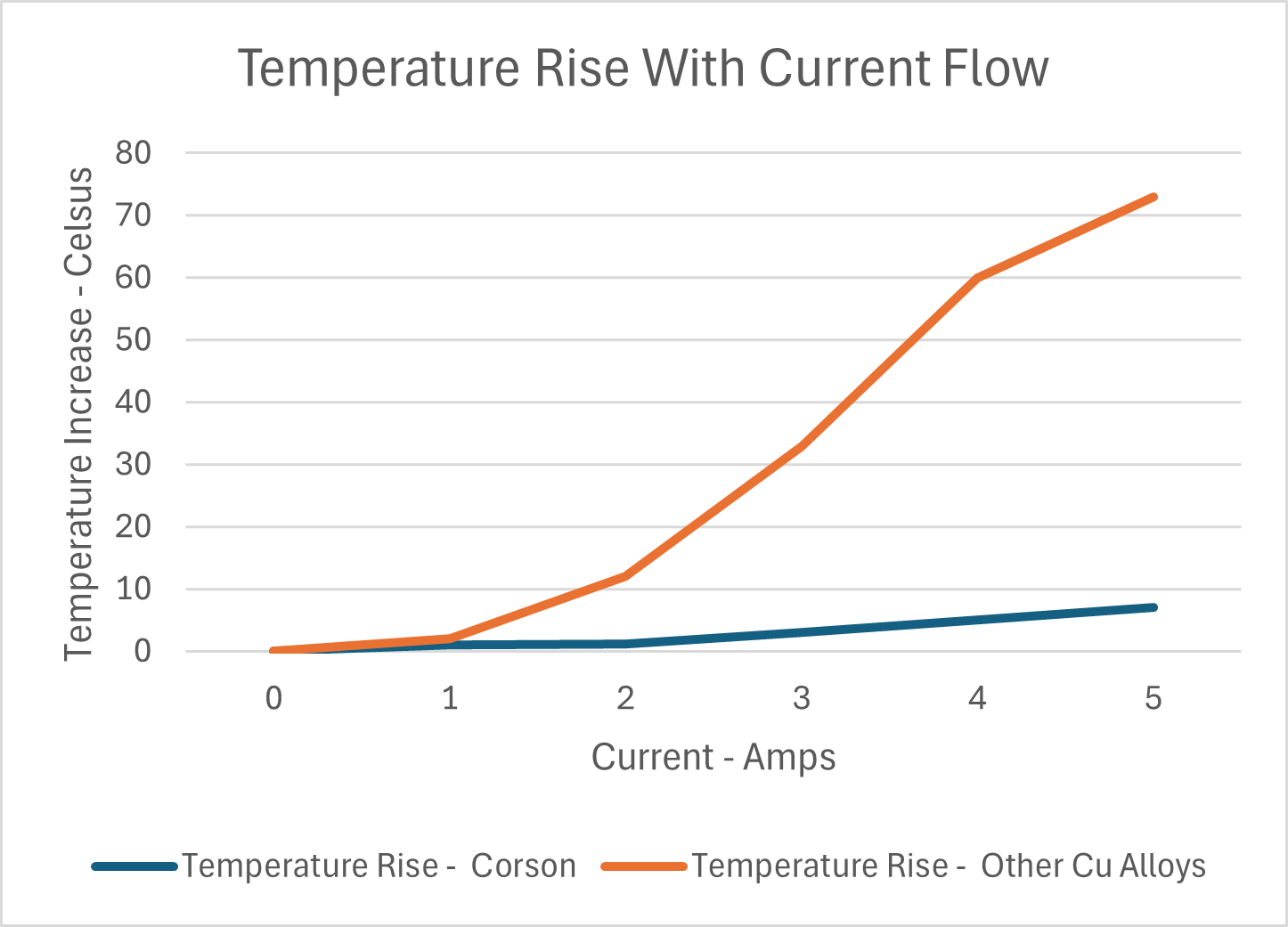

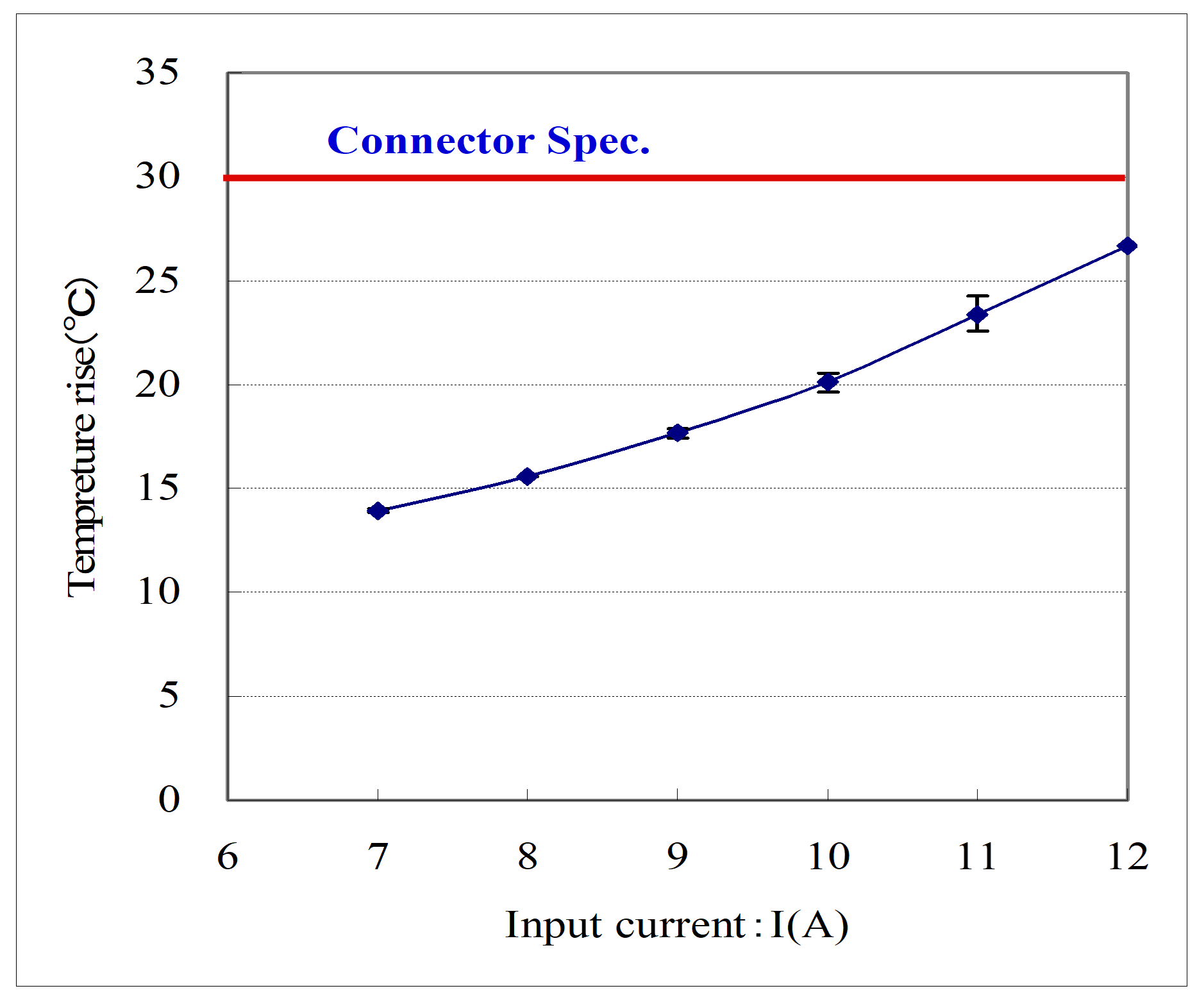

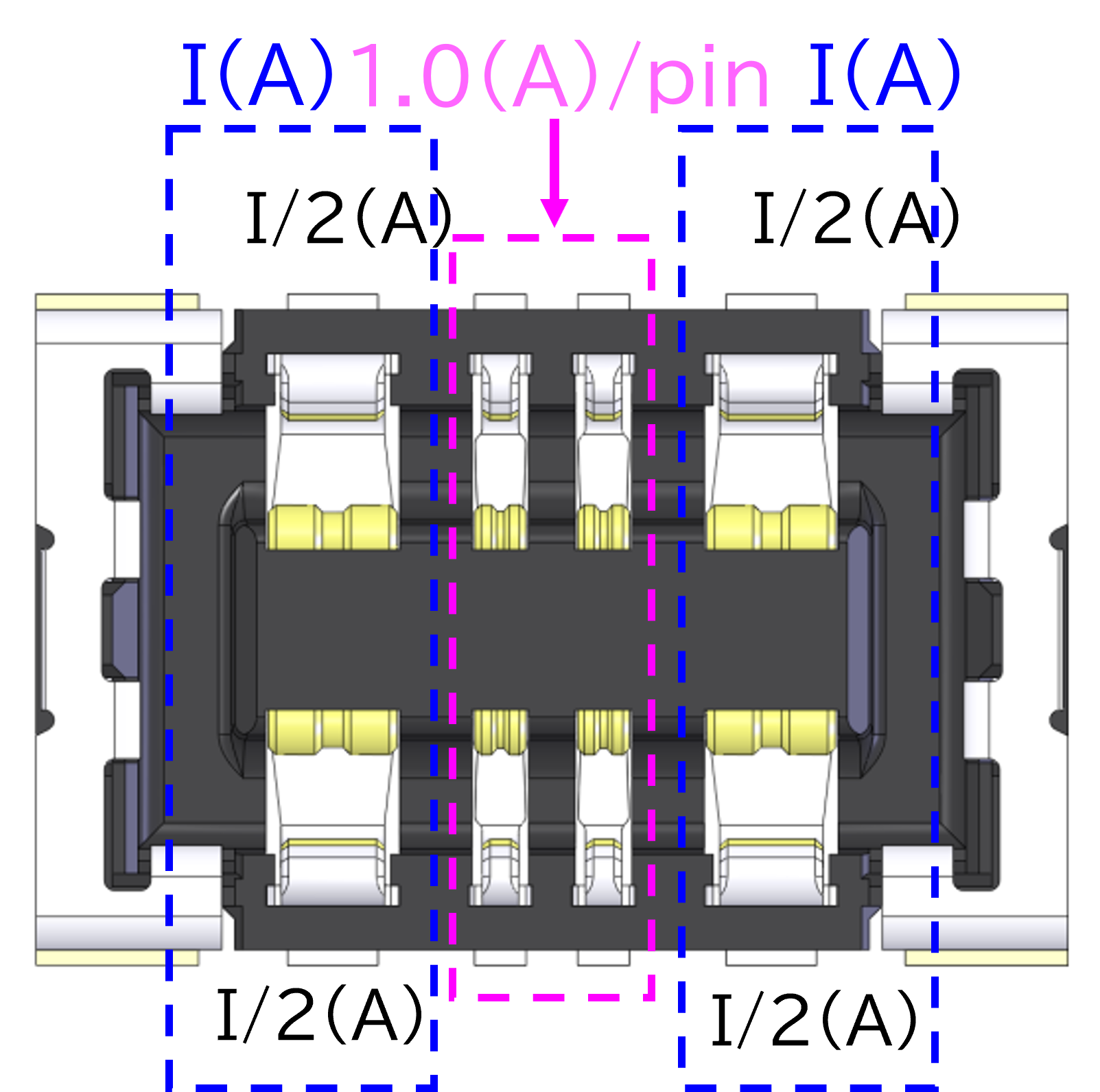

Power pins in NOVASTACK® connectors use high performance Corson's Alloy which is made by using Copper, Nickle and Silicon as main alloying elements. These pins provide higher mechanical and physical strength, better electrical and thermal conductivity, bend formability in high power delivery applications as compared to the copper only or copper alloy based contact pins. Excellent thermal resistance of Corson limits the temperature rise and helps to supress the heat generation during sustained high current flow as shown in the graph 1 below for reference only. At the sametime, the softening or bending of contact pins is also limted at higher temperatures using Carson as compared to coppor or Phosphor Bronze based pins. Graphs 2 shows that the maximum increase in the temperature of all 4 power pins of NOVASTACK®- B connector is limited to only 27.1 C with the maximum input current of 12 A and total current of 24 A, including the return GND current for connector as shown in figure below.

Power : I =7.0~12.0 A Signal : 1.0 A

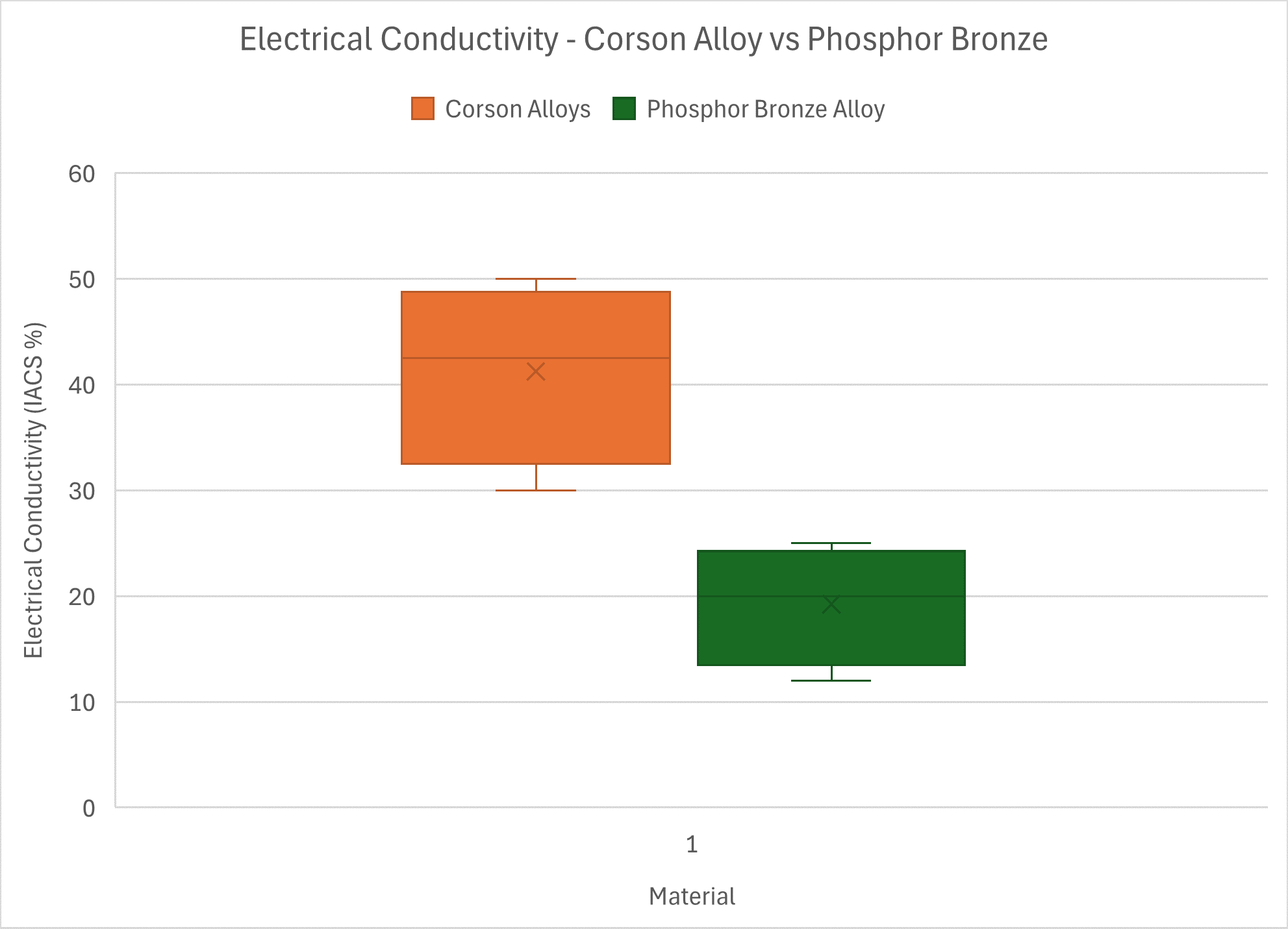

Corson Alloys generally have higher electrical conductivity (30–50 % IACS) compared to Phosphor Bronze alloys (12–25 % IACS) as shown in Graph 2 below. IACS stands for International Annealed Copper Standard

Higher electrical conductivity of connectors with Corson Alloy contacts makes them a preferred choice for power delivery in high operating temperatures, repeated mating and unmating, exposure to high humidity levels and high vibration and shock environments. Lower thermal stress at high temperatures and higher electrical conductivity of Corson Alloys result in longer life of NOVASTACK® series connectors as compared to connectors with contacts made of other Alloys like Phosphor Bronze or Copper, Nickel and Silicon types. Residual stress refers to the stress that remains within a metal or metallic structure even in the absence of external forces or loads. It is an important property of Alloys which plays a crucial role in maintaining the contact shape and functionality of contact pins used in connectors. Residual stresses in Corson alloy-based connectors are strategically controlled during the manufacturing process to ensure durability, maintain the contact shape, and provide consistent electrical and mechanical performance. By balancing compressive and tensile residual stresses, Corson alloys offer high reliability and longer life for contact pins used in connectors at high temperatures. Graph 3 shows high stress relaxation property for Corson Alloy at high temperatures and long duration, resulting in an excellent mix of high strength, excellent bend formability and high electrical conductivity as compared to other Copper and Phosphor Bronze type alloys.