Connectors Enabling Miniaturization and Portability in Healthcare 4.0

Miniaturization and Portability

As medical devices become smaller and more mobile, engineers face the challenge of shrinking every component – including the connectors. The trend toward wearable health gadgets, compact point-of-care devices, and portable diagnostics means connectors must deliver full performance in miniature packages. Modern medical connectors have evolved to be extremely low-profile and high-density, packing more connection capabilities into small form factors. A single mini connector today might handle what once required multiple connectors, saving space and weight. In fact, one compact connector can now host dozens – even over a hundred – of contacts in a tiny footprint, enabling complex devices (like imaging probes with micro-coaxial arrays) to funnel all signals through one interface. Such miniature high-speed medical connectors are critical for advanced diagnostics – they let designers achieve high channel counts and data rates without making the device bulky.

Design Strategies for Miniaturization

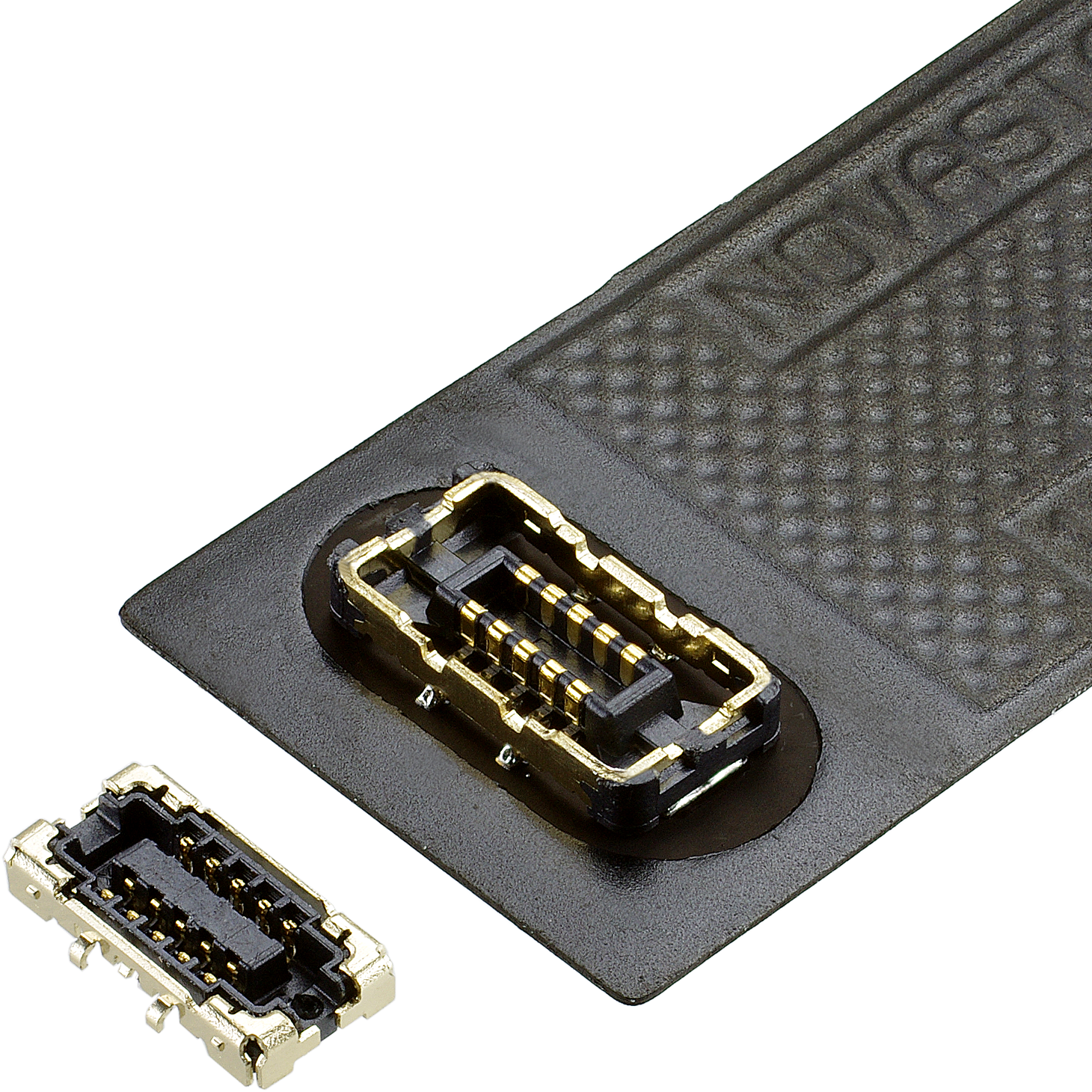

Several approaches are used to maximize functionality in a small device. Connectors with fine pin pitch and micro-scale housings are employed inside devices, allowing multiple boards or flex circuits to interconnect tightly. I-PEX’s NOVASTACK® board-to-board connector, for instance, provides high-speed stacking of PCBs with a very low mating height, ideal for multi-board assemblies in compact devices. FPC/FFC connectors like EVAFLEX® and ultra-thin FPC/FFC assemblies like MINIFLEX® allow routing of signals through tight spaces or around bends – useful in wearable designs. Another key strategy is multi-functional design – combining signal and power (and even fluidic or optical channels) into a single connector when possible. Fewer separate connectors mean fewer enclosure openings and a smaller footprint. Meanwhile, wireless communication can eliminate some external data ports, though even wireless devices need connectors for charging or backup links. For those, tiny I/O connectors such as micro dock connectors or coax power jacks are used.

I-PEX MHF® ultra-miniature RF coaxial connectors are a good example of enabling technology – they allow antennas for Wi-Fi, Bluetooth, or 5G to be integrated into wearables and portable monitors without sacrificing space. And when a device must physically dock to upload data or recharge, solutions like the MINIDOCK™ series provide robust yet compact docking connectors that can handle numerous mating cycles.

Balancing Size with Durability

A potential trade-off of extreme miniaturization is durability, so connector designers work to maintain robustness even as size shrinks. Medical devices still require connectors that can survive frequent connect-disconnect cycles and rough handling during daily use or patient movement. EMI shielding is also often built into small connectors to ensure that tightly packed electronics don’t interfere with each other. The latest miniature connector designs show that smaller doesn’t mean weaker – for instance, even micro-coaxial connectors now can include locking mechanisms and shielding for reliability. Connector makers like I-PEX have shown that “small, light, and durable” is an achievable trifecta for medical connectors. This empowers medical innovators to create portable and wearable devices that deliver clinic-grade performance on the go, without being encumbered by large connectors or cables.