極細同軸線/Twinaxial連接器

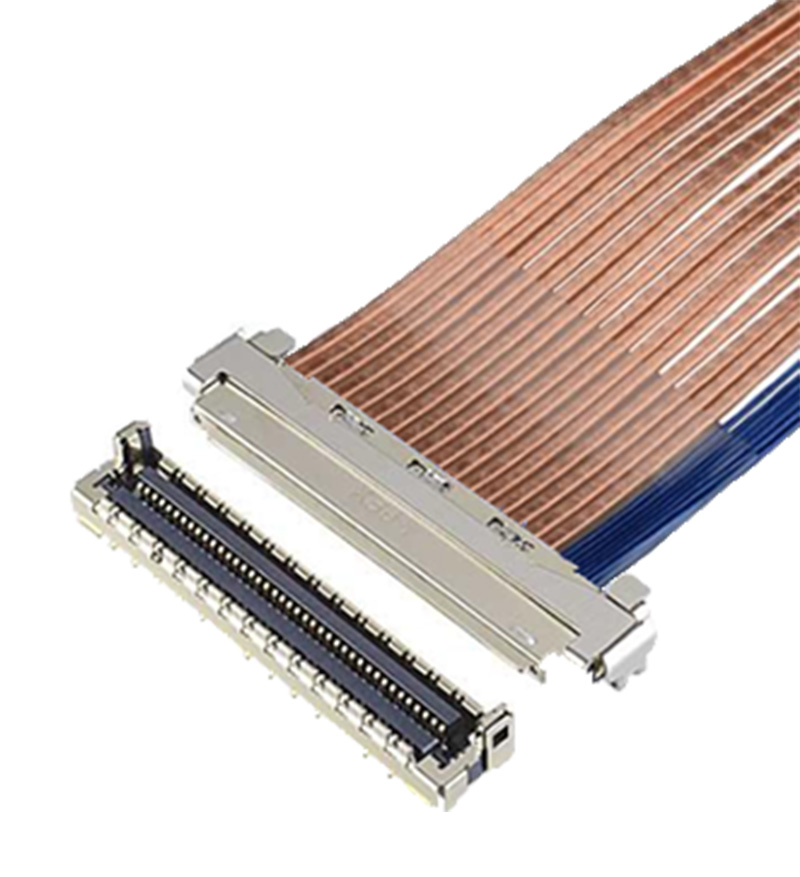

I-PEX is the pioneer of micro-coaxial connectors and mass produced the first CABLINE® micro-coaxial connector in 1996. Maximum operating frequency, available real estate, need for EMI shielding and required outer jacket/ Braid type are some of the important considerations in selection of optimal high speed Micro-coaxial and Twinaxial Cable Harnesses. Insertion Loss, Return Loss and VSWR are main losses in these harnesses which should be minimized by selecting the right size and length of cables and terminating them properly to the connector plugs. Depending on the required cable routing in designs, it is important to consider the bending, flexing and twisting properties of harnesses. Since the signal pin out, lay out and routing of board traces can vary in designs, different pin outs may be required for these harness assemblies. Most of the high speed protocols today, including USB 4, Thunderbolt, and PCIe Gen 6 and Gen 7 can be supported by these connectors and assemblies. The page also provides an overview of Harness Manufacturing process highlighting various steps involved.

Contents

- 1) Micro-Coaxial Cable Harness

- 2) Twinaxial Cable Harness

- 3) Maximum Operating Frequency

- 4) Available Real Estate For Connector

- 5) EMI Shielding and Power Signals

- 6) Minimizing the Losses

- 7) Bending, Flexing and Twisting Requirements

- 8) Pin Out Assignments

- 9) Jacketing and Bundling Types

- 10) High-Speed Protocols

- 11) Harness Manufacturing Process

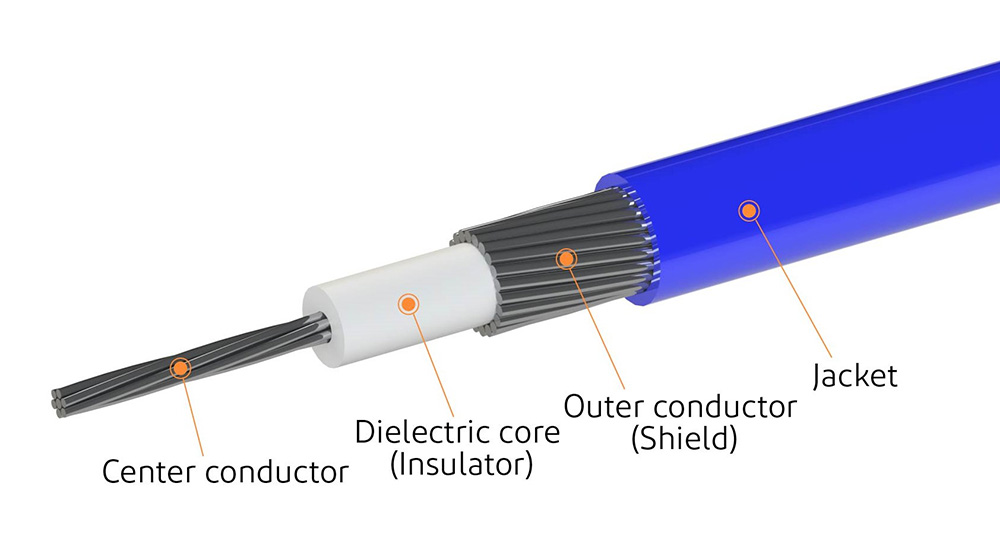

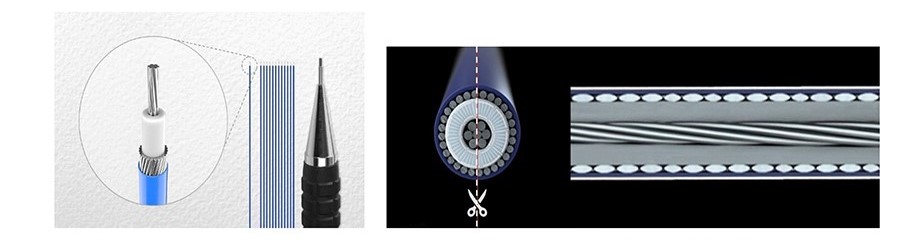

1) Micro-Coaxial Cable Harness

High frequency signals are more sensitive to electromagnetic radiation from near by communication sources like antennas, high speed board traces and transcievers on PCBs. By using Micro-coaxial cables, these high speed signals are well shielded from noise and signal integrity of data is preserved. A micro-coaxial cable includes a center conductor for signal transmission that is surrounded by dielectric core for insulation. There is outer metallic jacket with multiple strands for ground return current followed by jacket for additional insulation. I-PEX offers complete micro-coaxial cable harness solutions for high frequency signals by using its fully shielded connectors with optional mechanical locking feature for reliable connect by a dielectric.

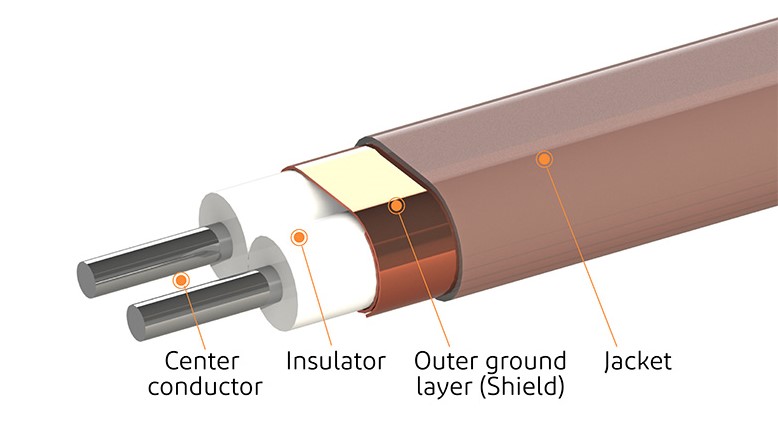

2) Twinaxial Cable Harness

Twinaxial cables are more suitable for high speed digital data transmission that uses low voltage, low skew and tightly phase matched signals. These cables also dissipate less heat and offer smaller signal losses than PCB traces, so they can be used to interconnect the devices on the board. A Twinaxial cable has two center conductors typically used for differential signals. The two conductors are separated and surrounded by insualator like rubber or plastic. There is a outer layer of dielectric around these conductors for insulation just like in Micro-coaxial cables. There is a metallic outer conducting shield for ground return current and outer PVC type jacket. I-PEX offers complete Twinaxial Cable Harness solutions for high speed differential signals by using its fully shielded connectors with optional mechanical locking feature for reliable connectivity.

Learn more: Twinaxial Cable Harness

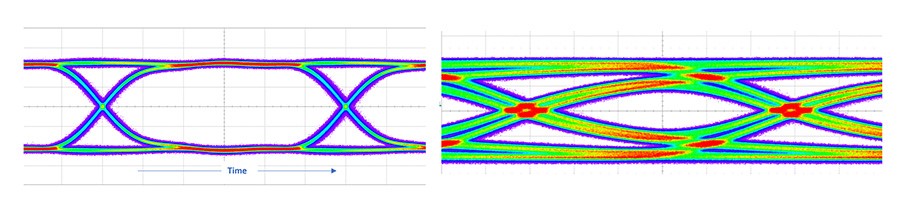

3) Maximum Operating Frequency

Maximum operating frequency determines how fast and how much of the data can be transmitted in a high speed interface of communication system. Impedance mismatch and high Insertion Losses of interconnect medium in high speed digital data transmission result in closed signal eye, leading to high Bit Error Rate and data loss on receiving end. For this reason, it becomes even more important to use a high performance, low loss cable interconnect with well matched impedance so that the high speed signals can be transmitted with high fidelity. CABLINE® series of products offer low losses and can operate up to maximum frequency of 16GHz and data rates can be supported up to 64Gbps using PAM4 signalling. USB, eDP, Display Port and PCIe are some of the commonly supported proctocols.

Learn more: Maximum Operating Frequency

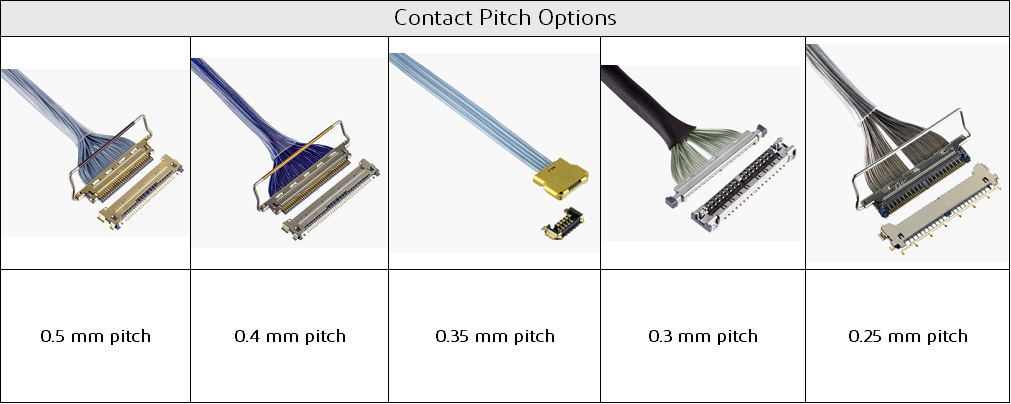

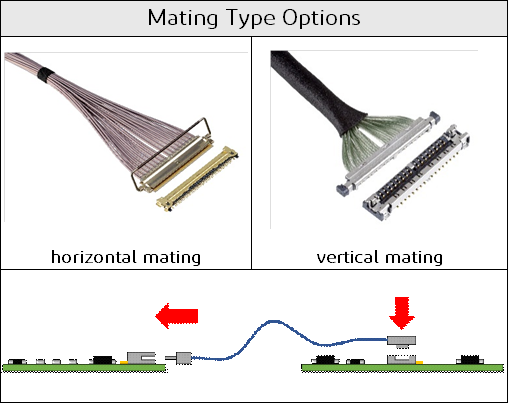

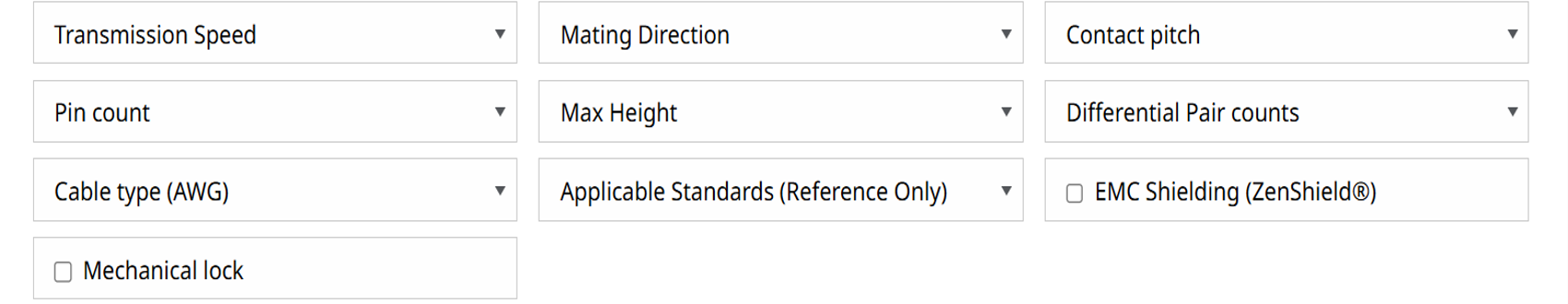

4) Available Real Estate For Connector

Number of channels in interface, required pin count, spacing between each pin, allowed mated width, length and profile height of plug and connector determine the type of suitable connector that should be used. Maximum available area and location of connector on PCB also determine the mounting configuration for receptacle and plug harness assembly, which can be horizontal or vertical . I-PEX offers connectors in both Horizontal and Vertical Mounting configurations and various different sizes and pin counts in its CABLINE® series of high speed connectors.

- Learn more: Available Real Estate For Connector

- How to Select a Micro-Coaxial Connector

- Mating Direction of Connectors

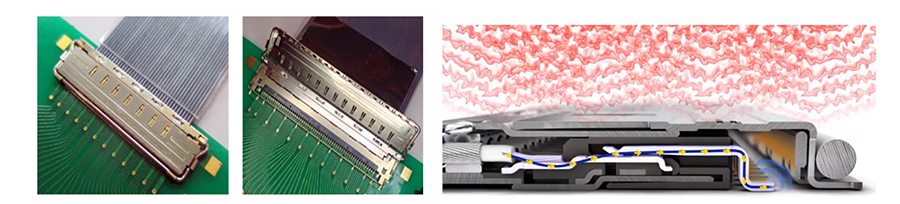

5) EMI Shielding and Power Signals

Sometimes there is a need to transmit power, low speed control and high speed data signals all in the same harness. Due to the close proximity of surface mounted components or noise present in the system, the signals need to be shielded from EMI and cross talk. I-PEX offers full 360 degrees EMI shielding solution, called ZenShield® on its plugs for both Flexible Printed Circuit Cable, Micro-coaxial cables, and Twinaxial in CABLINE® series products to cover both the signal contacts and the soldered tails of mated connector from EMI noise.

ZenShield® is offered in CABLINE® -VS II, CABLINE® -VS IIF, CABLINE®-CA II, CABLINE®-CA II PLUS, CABLINE®-CA IIP PLUS, CABLINE®-CA IIF, CABLINE®-CX II and CABLINE®-UM series products.

- Learn more: EMI Shielding and Power Signals

- ZenShield®: High-Performance EMC Shielding Connectors

- WEBINAR: EMC Shielding Connectors

6) Minimizing the Losses

Insertion Loss, Return Loss and VSWR are key performance indicators of High Speed Twinaxial and Micro-Coaxial Cable Assemblies. A high performance Micro-coaxial cable results in excellent signal integrity and reduced losses in high speed applications. At I-PEX we take pride to offer the high performance CABLINE® Micro-coaxial and Twinaxial Cable Assemblies which are built by using automated assembly processes to ensure consistent high quality and low losses in every finished product.

Learn more: Minimizing the Losses

7) Bending, Flexing and Twisting Requirements

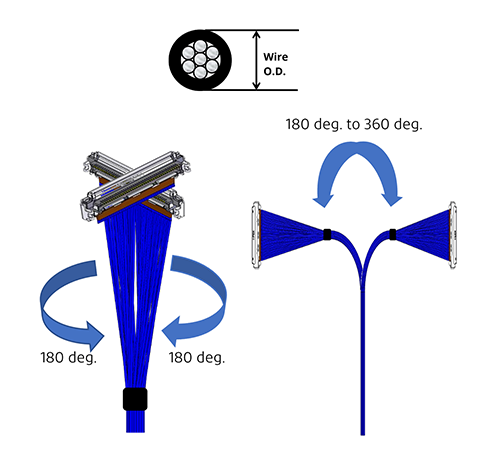

Both Micro-coaxial and Twinaxial cables are specified for Minimum Bend Radius, a parameter that determines how tightly these cables can be bent repeatedly with out being damaged and still ensuring high signal integrity. Minimum bend radius is typically measured in millimeters. Micro-coaxial cables are also specified for twisting, a parameter that allows the rotational movement of cable along the Y axis and is typically measured in degrees. When it comes to Micro-coaxial cables, the recommended minimum bending radius of cable is “6 times Wire O.D" but the actual specification depends on customer's selected coaxial cable.

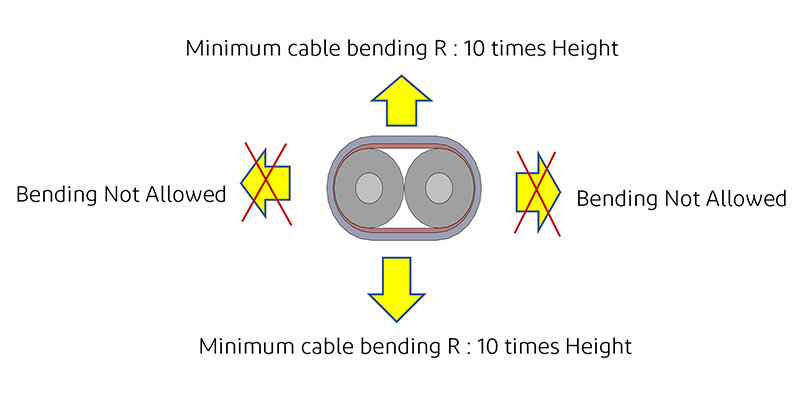

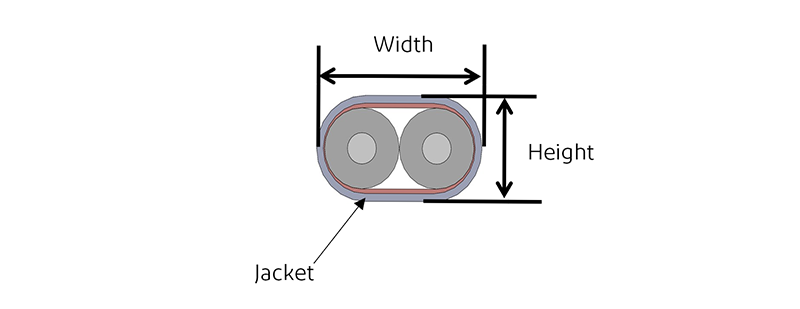

For Twinaxial Cables, the construction of cable restricts the bending and flexing in the direction of its height only as shown below. As a rule of thumb, the Minimum Bend radius for Twinaxial cables is specified as 10 times the height of cable. Bending and flexing side ways, along Y-axis is not allowed.

Learn more: Bending, Flexing and Twisting Requirements

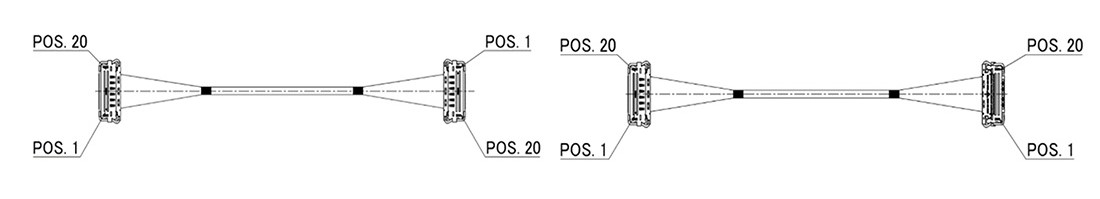

8) Pin Out Assignments

Depending on the signal pin out, lay out and routing of board traces, the pin assignments can be different on each connector in the harness assembly. Two different types of pin out configurations are offered in I-PEX high speed harness assemblies i.e. 1-N type straight pin out and 1-1 type mirror pin out configurations for routing and placement flexibility in designs.

Learn more: Pin Out Assignments

9) Jacketing and Bundling Types

Four different types of outer tapes or jackets are offered for high speed cable harnesses for increased routing and placement flexibility in designs. The bundling tapes can be wrapped around the cables at multiple points covering some, most or all of the cabling area of the harness. Also, there is flat bundle type option for space constrained systems that need light weight, transparent outer jacket with fast heat dissipation and uniform stress distribution.

Learn more: Jacketing and Bundling Types

10) High-Speed Protocols

USB 3, USB 4, Thunderbolt, Displayport, eDP, HDMI, MIPI and PCIe Gen 5 and Gen 6 are some of the commenly supported protocols with the maximum data rate of 64Gbps/Lane using PAM4 signal type.

I-PEX offers a tool which can be used to find the available connector options that are suitable for a specific industry standard such as MIPI, PCIe, USB etc. At the same time, it allows the users to see what types of industry standards are supported by each of I-PEX high speed connector family.

Signal Integrity Reference Tool

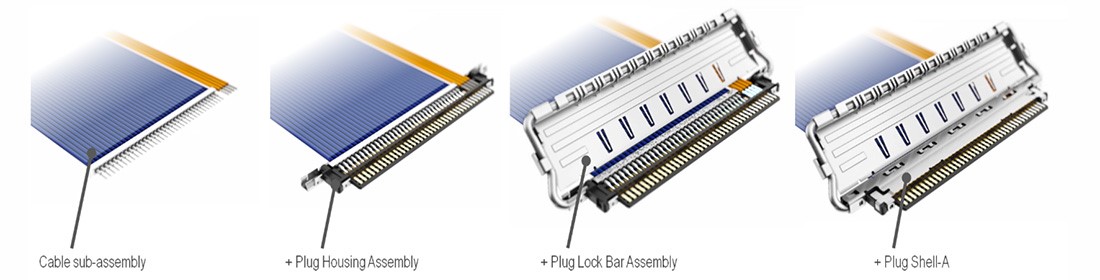

11) Harness Manufacturing Process

Main Process of Plug Harness Preparation is as follows:

- Strip and prepare cable sub-assembly

- Set the Cable Sub-Assembly to the Plug Housing Assembly part and solder the exposed conductor to the plug signal terminal

- Set Lock Bar Assembly (or Lock Bar) to Plug Housing Assembly parts

- Cover the plug shell and solder the required area to complete the plug harness

Learn more: Harness Manufacturing Process