MEMS Related Glossary

MEMS Devices

Application Technology

| LiDAR Technology | Image Stabilization Technology | Infrared Camera Technology | Localized Vacuum Technology |

MEMS Devices

MEMS Accelerometers

Acceleration sensors are sensors that detect changes in velocity per unit time.

Acceleration sensors are sensors that detect changes in velocity per unit time.

Typical acceleration sensors contain springs and weights. When an object moves or acceleration is applied, the weight tries to move due to inertia, and the spring stretches or shrinks by being pulled by the weight. By measuring the degree of this deformation using methods such as “capacitance,” “resistance,” and “piezoelectric effect,” it is possible to measure how much acceleration is being applied and in which direction.

MEMS accelerometers are very small and are used in a wide range of applications, including smartphones, game controllers, drones, car airbag systems, and even seismometers and activity meters. MEMS accelerometers are often used together with gyro-sensors to accurately determine position and direction in smartphones and augmented reality (AR) applications.

MEMS Gyro Sensors

Gyro sensors are sensors that measures angular velocity (the speed of rotation around an axis).

Gyro sensors are sensors that measures angular velocity (the speed of rotation around an axis).

While accelerometers respond to linear motion, gyro sensors respond to rotation. For example, when we hold a smartphone and rotate it, the screen detects the rotation and the camera and game screen also rotate.

MEMS gyro-sensors are very small and contain a small structure called an “oscillator” inside. When this structure is vibrating in a fixed direction and an object rotates, a physical phenomenon known as the Coriolis force is triggered, causing a slight change in the direction of vibration. By measuring this change as an electrical signal, the sensor can detect “in which direction” and “how fast” the object has rotated. This mechanism that utilizes the gyro effect is called a "Coriolis -type gyro."

MEMS gyro sensors are often used together with acceleration sensors. For example, devices such as smartphones and drones combine both acceleration and rotation information to accurately detect how much and in which direction they are moving.

MEMS Speakers

Typical speakers make sound by converting electrical signals into air vibrations with the use of magnets and coils.

Typical speakers make sound by converting electrical signals into air vibrations with the use of magnets and coils.

However, this method requires a certain size and many components, which limits miniaturization and power saving. the operating mechanism of MEMS speakers differs from that of typical speakers in that they are composed of very small mechanical components and electronic circuits using semiconductors, and they use “electrostatic force” or “piezoelectric effect” to vibrate membranes.

For example, in electrostatic MEMS speakers, very thin membranes and electrodes are arranged together, and when a voltage is applied between them, the membranes are attracted back and forth by the force of static electricity. This movement vibrates the air and creates sound.

In the case of piezoelectric MEMS speakers that use piezoelectric elements, the piezoelectric membrane is used in the diaphragm section. The electrical signal is converted into mechanical vibration by the piezoelectric film, creating sound.

The most significant feature of MEMS speakers is their small size and light weight. This allows them to be integrated into very small devices such as earphones and hearing aids, where space is limited. They are also energy efficient, making them ideal for wearable devices that are in use for long hours. It is expected that MEMS speakers will be used in a wide range of next-generation devices such as smart glasses and AR/VR.

KRYSTAL Wafer's single-crystal PZT film has high voltage resistance and large displacement, enabling strong sound pressure. Furthermore, its low dielectric constant contributes to reduced power consumption.

MEMS Microphones

MEMS microphones are very small microphones made using semiconductor processing technology, and play a very important role in everyday products such as smartphones, earphones, AI speakers, and smart home appliances.

MEMS microphones are very small microphones made using semiconductor processing technology, and play a very important role in everyday products such as smartphones, earphones, AI speakers, and smart home appliances.

Like MEMS speakers, MEMS microphones also have “electrostatic” and “piezoelectric” types. However, contrary to speakers, sound in the air vibrates the membrane, and the energy is converted into an electrical signal.

The basic structure of an electrostatic MEMS microphone consists of a thin membrane (diaphragm) that is moved by air vibrations and a fixed electrode (backplate) that detects the movement. When air vibrations hit the diaphragm, the membrane moves slightly. This movement changes the distance between the diaphragm and the back plate, resulting in a change in "capacitance. The electronic circuit reads this change and processes it as an electrical signal.

In the case of piezoelectric MEMS microphones, a piezoelectric membrane is used in the diaphragm. When the piezoelectric membrane receives sound, the membrane vibrates and the piezoelectric membrane converts the vibration into an electrical signal.

KRYSTAL Wafer's high piezoelectric properties and low dielectric constant are expected to produce a large output charge. This allows for an excellent signal-to-noise ratio, making it possible to detect even the smallest of sounds.

MEMS Pressure Sensors

Pressure sensors are devices that measure how much force is applied per unit area and convert it into an electrical signal for output.

Pressure sensors are devices that measure how much force is applied per unit area and convert it into an electrical signal for output.

MEMS pressure sensors are very small and high performance. They use silicon material to create a thin, tiny membrane and measure how much this membrane deforms under pressure.

There are several different methods for measuring this deformation. The piezo-resistive method uses a piezoelectric thin film, and when the film is deflected by pressure, the electrical resistance changes, and this change is measured as an electrical signal to determine the magnitude of the pressure. Other methods include those that measure changes in capacitance and those that use light to measure deformation.

Small and lightweight MEMS pressure sensors are used in many small devices, for example, in automobile tires to constantly monitor tire pressure, or in smartphones and smartwatches to predict altitude and weather conditions based on changes in air pressure. They are also used in the medical field, for example, in capsule-type sensors that measure blood pressure inside the body and in devices that measure breathing pressure.

MEMS Ultrasonic Sensors

Ultrasonic sensors use ultrasonic waves, which are high-frequency sounds inaudible to humans, to measure the distance between objects , and to examine the shape of objects.

Ultrasonic sensors use ultrasonic waves, which are high-frequency sounds inaudible to humans, to measure the distance between objects , and to examine the shape of objects.

The basic mechanism of an ultrasonic sensor is to send out ultrasonic waves and measure the time it takes for the waves to hit and bounce back from an objects to detect the surrounding objects.

MEMS ultrasonic sensors integrate a “transmitter” that emits ultrasonic waves and a “receiver” that receives them. By using MEMS technology, the vibrating membrane can be made very thin and uniform, enabling stable ultrasonic output and reception.

Piezoelectric ultrasonic sensors use PZT membranes for transmitting and receiving. KRYSTAL Wafer's piezoelectric films have high piezoelectric properties and low relative permittivity, so large output charges can be expected.

Compact, high-performance MEMS ultrasonic sensors are used in smartphones, drones, self-driving cars, and even in the medical field.

For example, in smartphones, they are used in functions that automatically turn off the screen when the screen is placed to the ear. They are also used in drones and work robots as sensors to avoid surrounding obstacles, and are indispensable for safe movement in space.

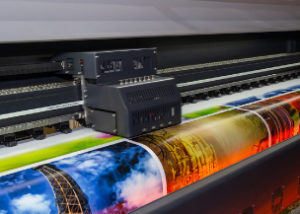

Inkjet Printer Head

Inkjet printers are printers that draw pictures and text by spraying fine ink drops onto paper, and the part that “sprays” the ink onto the paper is called the printer head.

Inkjet printers are printers that draw pictures and text by spraying fine ink drops onto paper, and the part that “sprays” the ink onto the paper is called the printer head.

The MEMS inkjet printer head has a large number of nozzles of very small size to eject ink, and ink is ejected from these nozzles. This enables smooth and detailed printing, as seen in the photo. In addition, since the amount and color of ink can be fine-tuned, color reproduction is also very high, and this technology is used in a wide variety of fields, from home-use to high-end printers for industrial use.

Furthermore, this MEMS inkjet printer head has applications beyond printing. For example, in the medical and biotechnology fields, it is used as a device to precisely and finely drop liquid medicine. And when a tiny amount of liquid needs to be handled for DNA analysis or cell observation, high-precision liquid control such as that provided by MEMS inkjet printer heads can be useful.

There are two main methods for this ink extrusion mechanism.

One uses heat, in which small heaters inside the nozzle heat the ink for a brief moment, resulting in a sudden expansion of the ink and the formation of bubbles that push the ink out of the nozzle.

The other method uses piezoelectric elements, which use special materials that change shape when electricity is applied to push a chamber of ink to eject it.

KRYSTAL Wafer's single-crystal PZT films have large displacement and low dielectric constant, so heat generation during drive is suppressed, which reduces the heat load on the circuit side and is expected to achieve higher density.

RF Filters

Radio waves that can be used as carrier signals for wireless communications used when connecting to the Internet via Wi-Fi or receiving TV or radio are called “radio frequencies (RF),” and there are many different types of frequencies used depending on the communication method. RF filters are used to extract only the necessary signals from these many radio frequencies and remove unnecessary noise. For example, in a smartphone, it is necessary to select only the 4G and 5G frequency bands used for the Internet and block other mixed signals.

Radio waves that can be used as carrier signals for wireless communications used when connecting to the Internet via Wi-Fi or receiving TV or radio are called “radio frequencies (RF),” and there are many different types of frequencies used depending on the communication method. RF filters are used to extract only the necessary signals from these many radio frequencies and remove unnecessary noise. For example, in a smartphone, it is necessary to select only the 4G and 5G frequency bands used for the Internet and block other mixed signals.

There are several types of RF filters, especially for small devices such as smartphones, “surface acoustic wave (SAW) filters” and “bulk acoustic wave (BAW) filters” are used, and piezoelectric films are used in these filters. Advanced RF filters using piezoelectric MEMS technology make it possible to create high-performance filters with even smaller structures, contributing greatly to the miniaturization and performance of smartphones.

In the future, as next-generation communications such as 5G and 6G advance, the frequency bands used will increase and more and more RF filters will be needed. For this reason, piezoelectric MEMS-based RF filters, which are smaller and more efficient at sorting out radio waves, are being developed and will play a key role in supporting communication technology.

MEMS Autofocus

When taking pictures with a smartphone camera, the function that automatically focuses the camera is called "Autofocus."

When taking pictures with a smartphone camera, the function that automatically focuses the camera is called "Autofocus."

This focusing technology is actually very complex, and it also needs to move very fast and accurately. The advantage of using MEMS technology is that it is smaller, lighter, more energy-efficient, and less prone to failure than mechanical systems because the microscopic structure is made on a silicon substrate.

There are several methods of autofocusing. Basically, a very small actuator (driving device) moves the position of the lens back and forth to adjust it to a position where light is focused on the sensor appropriately. In addition to moving the position of the lens, there are also methods developed to change the focal length of light by changing the shape of the fluid in the lens.

MEMS autofocus is used not only in smartphones, but also in tablets, drones, industrial inspection cameras, and medical equipment cameras.

MEMS Mirrors

MEMS mirrors are devices that use extremely small mirrors to reflect and change the direction of light, and can automatically and quickly move very small movements of less than a few millimeters using electrical signals.

MEMS mirrors are devices that use extremely small mirrors to reflect and change the direction of light, and can automatically and quickly move very small movements of less than a few millimeters using electrical signals.

The structure of a MEMS mirror consists of a tiny mirror supported by fine springs and axes, and the mirror is rotated and tilted using electrostatic, piezoelectric, and electromagnetic methods. This allows laser or projector light to be directed to a precise position, so MEMS mirrors are used to swing lasers in different directions at high speed, to project high-resolution images, and to control the position of light with extreme precision.

For example, MEMS mirrors are also used in a technology called LiDAR (Lidar); with MEMS mirrors, LiDAR can be made smaller and lighter, making it easier to mount on cars and drones.

Despite their extremely small size, MEMS mirrors can operate with high speed and precision, making them useful in a variety of applications where light can be manipulated at will. In the future, MEMS mirrors are expected to play an important role in new imaging technologies such as augmented reality (AR) and virtual reality (VR).

MEMS Optical Switches

MEMS optical switches are devices used to switch the path of light in optical communications and are extremely miniaturized using MEMS technology.

In today's society, communications via the Internet, smartphones, TVs, etc. are often sent through optical fiber, and the signals running through them are "light signals. In order to control optical signals, we need to switch that light to a different route when necessary.

Usually, there are many switches that use electrical signals to switch, but in optical communications, it is more efficient and faster to switch signals “as light”. For example, the mirror system physically changes the direction in which light travels by electrically moving a minute mirror reflector. The mirrors in these switches are very small, only a few micrometers in size, but they can be moved precisely using MEMS technology. The advantage of this technology is that it can handle signals in the form of light, which means that there is no need to convert them into electrical signals, so there is little information loss and the speed is very fast.

Because MEMS optical switches perform these operations with electrical signals, they can switch at very high speeds and consume very little energy, making them especially important in large-scale communication networks. For example, large data centers and telecommunication base stations are lined with large numbers of optical fibers. In these locations, optical signal paths must be switched instantaneously in response to traffic conditions or failures. For this reason, MEMS optical switches are used to automatically switch to the optimal route to ensure that communication is always smooth.

MEMS Micro Pumps

MEMS micropumps are very small pumps, made of micrometer-sized components using MEMS technology.

The basic structure of a MEMS micropump is made of materials such as silicon or glass, with a small chamber and valves inside, which are pushed or pulled to move the fluid. Using electrostatic force, piezoelectric effect, or electromagnets, a thin membrane moves up and down, pushing the fluid in one direction. The system is compact, lightweight, and capable of continuously conveying minute amounts of fluid. The ability to accurately move very small amounts of liquid that cannot be handled by human hands is a major advantage.

This technology is of particular interest in the medical field. For example, it is used in devices such as insulin pumps, which allow diabetes patients to automatically inject a fixed amount of medication into their bodies. MEMS micropumps are also used in miniaturized laboratory equipment to precisely control the speed of intravenous drips and to mix chemicals in minute quantities. Other applications include ink delivery in inkjet printers, microscopic fluid control in cooling systems, fuel supply for small drones, and many others.

MEMS Flow Sensors

MEMS flow sensors create microscopic pathways (microchannels) in a silicon substrate and detect the movement of gas or liquid flowing through them. There are several detection methods. For example, in the “thermal flow sensor method,” a heating element is placed in a portion of the flowing passage, and temperature sensors are placed in front of and behind the element. As the fluid flows, heat is carried by the fluid, resulting in a change in temperature distribution. The flow rate is calculated from this temperature change.

Using MEMS technology, these elements and sensors can be made very small and precise, and can respond immediately to minute changes in the flow. Furthermore, because the body of the flow sensor is so small, it can be integrated into tight spaces or inside the body. In the medical field, such MEMS flow sensors are used in ventilators and intravenous infusion devices to accurately control the state of a patient's breathing and the amount of medication to be administered. They are also used in factories to monitor the flow of gases and chemicals in real time and in automobiles to manage fuel supply.

MEMS Resonators

Resonators are devices that cause a phenomenon called “resonance” at a specific frequency, and MEMS resonators realize this mechanism in a very small structure.

MEMS resonators are made of small beams or plates of silicon, which are electrically vibrated to cause resonance at a specific frequency. This is used as an “oscillator” to measure time, a ‘filter’ to stabilize signals, and a “frequency standard” to use as a frequency reference. Crystal oscillators" using quartz crystals have been used in the past, but MEMS resonators have the advantage of being smaller and easier to manufacture than quartz crystals.

The appeal of MEMS resonators is that they are highly accurate, resistant to temperature changes, and can generate extremely stable frequencies despite their minute structure.

Smartphones and GPS devices require oscillators to maintain accurate time and frequency, and MEMS resonators can achieve this in a size of only a few millimeters or less.

MEMS Vibration Energy Harvesters

MEMS Vibration Energy Harvesters are gaining attention as “small generators” to run without batteries.

The MEMS Vibration Energy Harvester is especially useful in places where batteries cannot be replaced or in systems with many small sensors. For example, sensors installed in bridges, buildings, and machinery can sense structural distortions and vibrations and keep moving on their own, generating power from the vibrations themselves.

There is also potential for applications in wearable devices and smart watches. For example, the small vibrations transmitted by a bag or clothing worn by a person could be used to generate electricity. By using the tiny vibrations generated by human movement to generate electricity, it may be possible to create smart devices that do not require recharging.

Another advantage is that it is environmentally friendly. By reducing the use of disposable batteries, less waste will be produced and the environmental impact will be reduced. Such “self-powered sensor systems” will be a very important technology for a sustainable society in the future.

MEMS Smell Sensors

MEMS smell sensors are sensors that sense odor molecules in the air and convert them into electrical signals, just like the human nose, and are compact and high-performance using MEMS technology.

Smells are actually perceived by a very small amount of chemical substances (gases) contained in the air. The human nose detects these substances and judges them as “sweet” or “smelly,” and MEMS smell sensors attempt to reproduce this function using a machine.

In the case of piezoelectric odor sensors, a piezoelectric film coated with a sensitive film that reacts to odor molecules is vibrated to detect slight changes in the resonance frequency of the piezoelectric film caused when the odor molecules adhere to the sensitive film.

MEMS smell sensors are expected to be used in various fields, such as food freshness checks, gas leak detection, and health checks.

For example, if this sensor is attached to a refrigerator, it can detect changes in odor and issue an alarm when the food inside is damaged, and it is also being studied for medical applications to detect signs of illness at an early stage by measuring components in breath.

More recently, the system has been combined with AI to learn patterns of smell for more accurate analysis. In other words, machines are now able to “smell,” “remember,” and “judge” smells, similar to how humans function.

Application Technology

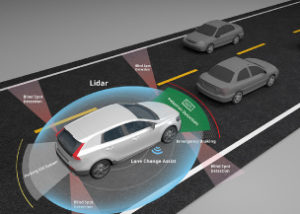

LiDAR Technology

LiDAR (Light Detection and Ranging) is a technology that uses laser light for detection and distance measurement. It is considered especially important in automatic driving, but has come to be used in a broad range of applications recently, including mobile phones.

LiDAR (Light Detection and Ranging) is a technology that uses laser light for detection and distance measurement. It is considered especially important in automatic driving, but has come to be used in a broad range of applications recently, including mobile phones.

Applications

E.g.: Automatic driving; advanced driving support systems

Image Stabilization Technology

Piezoelectric materials are used in positional control devices such as camera shake correction mechanisms for digital cameras.

Piezoelectric materials are used in positional control devices such as camera shake correction mechanisms for digital cameras.

Applications

Digital cameras

Infrared Camera Technology

Pyroelectric infrared sensors use the effects of pyroelectric ceramics to detect infrared light. The spontaneous polarization of the piezoelectric material causes a temperature change when the infrared light is received, and an electric charge proportionate to the pyroelectric coefficient is generated in the optic receiver. This charge is immediately neutralized, but the sensor detects the voltage that is generated instantaneously at that moment.

Pyroelectric infrared sensors use the effects of pyroelectric ceramics to detect infrared light. The spontaneous polarization of the piezoelectric material causes a temperature change when the infrared light is received, and an electric charge proportionate to the pyroelectric coefficient is generated in the optic receiver. This charge is immediately neutralized, but the sensor detects the voltage that is generated instantaneously at that moment.

Applications

E.g.: Motion sensors, air conditioners

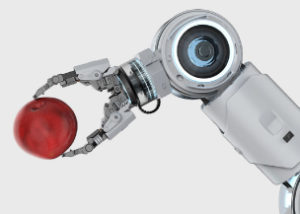

Localized Vacuum Technology

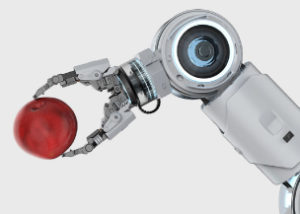

A technology called “local vacuum” has gained attention as a near-future technology that could become a reality through the use of KRYSTAL Wafer’s PZT film. For example, a micro-pump driven by the piezoelectric properties of PZT film can be used to generate a low-level vacuum. This micro-pump could then be attached to the end of a robot arm, allowing the robot arm to hold onto an object. Using this PZT film simplifies the design dramatically, because only a power cable is required to drive the unit.

A technology called “local vacuum” has gained attention as a near-future technology that could become a reality through the use of KRYSTAL Wafer’s PZT film. For example, a micro-pump driven by the piezoelectric properties of PZT film can be used to generate a low-level vacuum. This micro-pump could then be attached to the end of a robot arm, allowing the robot arm to hold onto an object. Using this PZT film simplifies the design dramatically, because only a power cable is required to drive the unit.

Applications

Industrial robot arms